"Our communication here is a failure." The famous movie "cool hand road" often applies to marketing and manufacturing departments. Don't misunderstand me, marketing must be the king. If they can't sell it, it doesn't make sense. But sometimes simple changes in packaging make sales easier, which means lower costs and higher profits. Therefore, marketing and manufacturing must start from the beginning and say, "if we can... That wouldn't be cool. "

Do you think there's nothing wrong with the trifles? Simple changes can save millions of dollars. Every two percents are increased by one additional week per year. This could be the sale of hundreds of thousands or millions of extra products.

Here are three, real life, examples:

1. Simplify package styles to minimize or eliminate changeovers.

If you bring in Manufacturing early during the package design phase, you may be able to prevent unnecessary costs and headaches.

For example, cartooning machines can run reverse tuck or straight tuck cartons but not both on the same machine. One company ran straight tuck cartons and changing over the packaging line between products took about 45 minutes. Then Marketing specified a reverse tuck for a new product. Changing from straight to reverse, or back, takes more than five hours. Marketing agrees that there is no structural or marketing reason for the reverse tuck but, now that it is in production, they are reluctant to change it.

.png)

2. Standardize sizes to boost efficiency.

Here’s one time when “close enough” definitely doesn’t cut it. Several of this company’s cartons were similar in size. Standardizing size where possible would have added enough additional production time to offset any material costs many times over.

You’ll see this card hanging by the checkout counter. The company made more than 800 stock-keeping units (SKUs) for its own and other brands. About half the cards were 1/8-inch longer than the others. No reason for it, it just happened somehow. Going from ship-from-stock to make-to-order, the company increased market share by 8%. The downside, though, was many more changeovers and the delay caused by two different cards. It cost $400 per card to standardize but standardization allowed the company to go from four shifts down to two.

.png)

Count was another issue. Changing from a 4- to 8-count pack, and back, was easy. Going to 6 and back was time consuming. The plant manager argued for standardizing on just 4 and 8 but Marketing thought there was customer demand for a 6-pack—so it stayed.

3. Eliminate unsightly label skew to create a more attractive package.

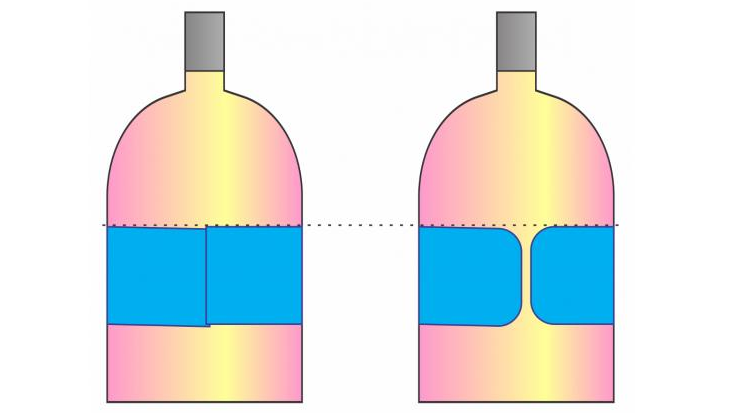

Full-wrap labels on round bottles are sensitive to skewing, where the ends do not align. It may be machine-, label- or bottle-related but the entire customer sees is an imperfect product that reflects poorly on your brand and often goes unpurchased. Where the label ends meet, even a skew as small as a 32/100-inch is noticeable and the plant will drive itself nuts trying to eliminate it.

The problem of skew, if not the skew itself, can be eliminated by using slightly less than a full wrap, leaving a gap between label ends. Any little skew becomes invisible to the customer. Adding a radius to label corners is even better.

Marketing must always have the final decision, but it must be an informed decision. It can only be an informed decision with early input from Manufacturing. Get to know your colleagues so you feel comfortable talking to them, and make communication a regular aspect of your relationship. It will pay off for both sides.

There are so many packaging on equipmentimes.com, which can help to save much time in packaging, and let you have much time to promote your products. The following will offer you one of the Liquid Packing Machine, which is called carbonated drink filling machine.

Main Features of 1L liquor drinks bottling machine/ carbonated drink filling machine for wholesale

1. 1L liquor drinks bottling machine/ carbonated drink filling machine for wholesale is mainly used for all kinds of gas filling after mixed drinks, carbonated drinks, sodas, carbonated beverage, carbonated soft drink, fruit juice drinks, mineral water, alcoholic drinks, etc.

2. Advanced programmable PLC is equipped to control small carbonated soft drink filling machine.

3. Working speed of 1L liquor drinks bottling machine/ carbonated drink filling machine for wholesale can be adjusted by frequency conversion device.