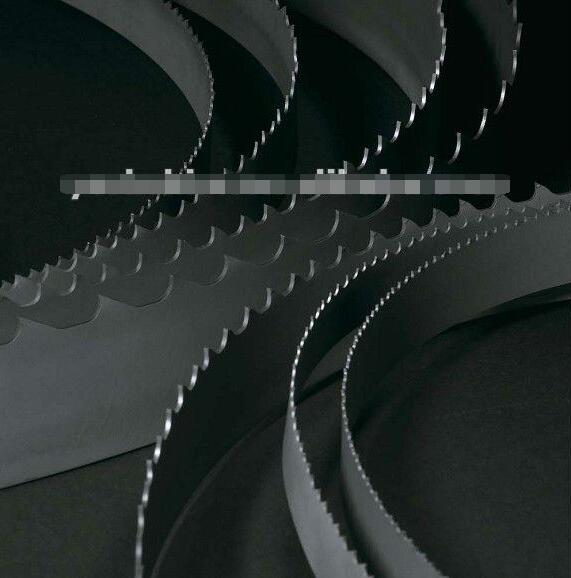

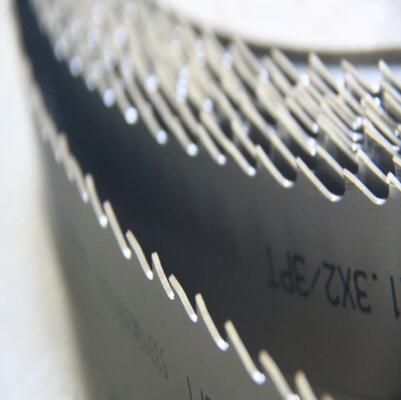

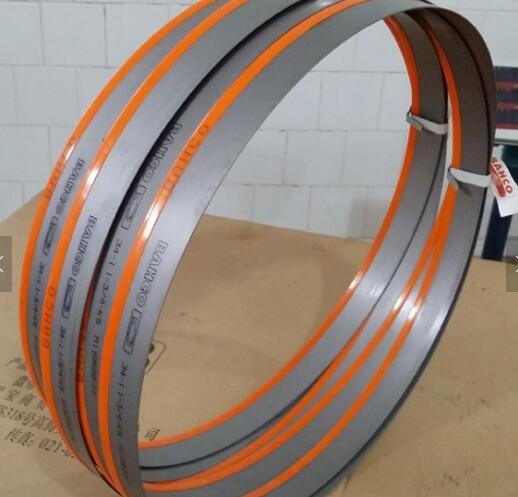

TCT band saw blades for cutting metal

1.High abrasive resistance; 2.High red hardness; 3.unbreakable teeth; 4.excellent cutting performance.

easy cutting cutting mental band saw blade

1.High abrasive resistance; 2.High red hardness; 3.unbreakable teeth; 4.excellent cutting performance.

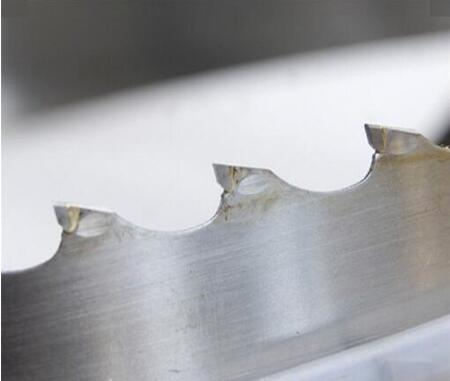

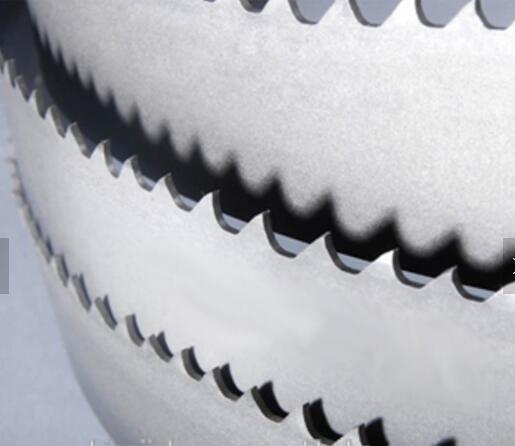

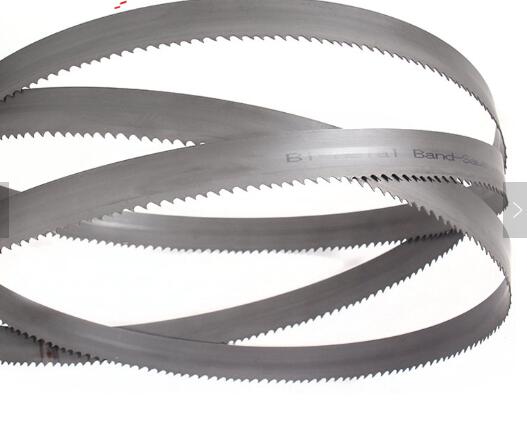

wear-resistance m42 bimetal band saw blade

M42 for the teeth and alloyed tool steel as the backing material ,are joined during the high energy laser welding process.

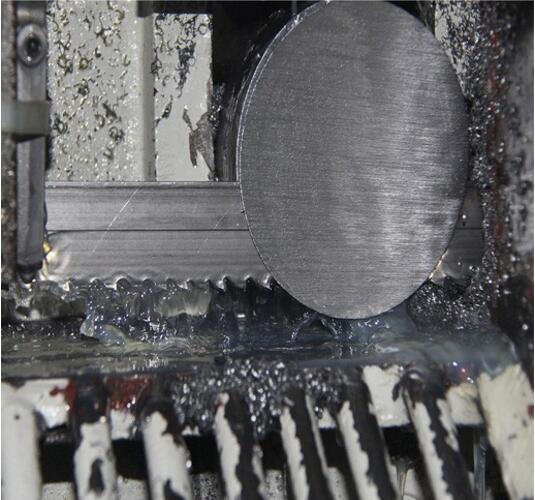

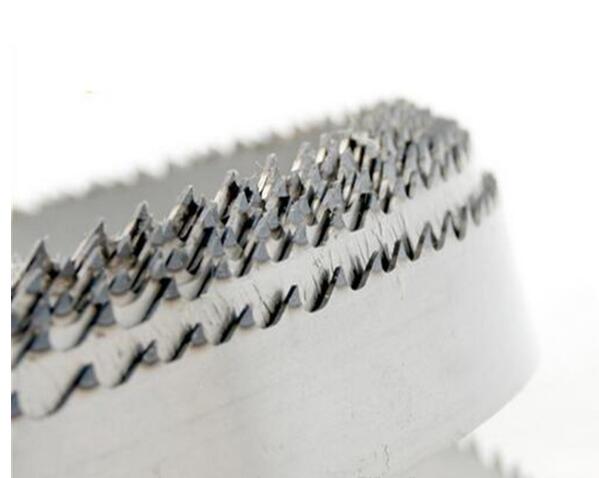

good stability cutting metal band saw blades

1.High abrasive resistance; 2.High red hardness; 3.unbreakable teeth; 4.excellent cutting performance.

manufacturer Latest price band saw blade

Bi-metal Bandsaw Blades are made of imported M42 high speed steel for edge and spring steel for backer by means of a series of advanced equipment and technique processing such as electron beam welding and specific heat treatment, etc.

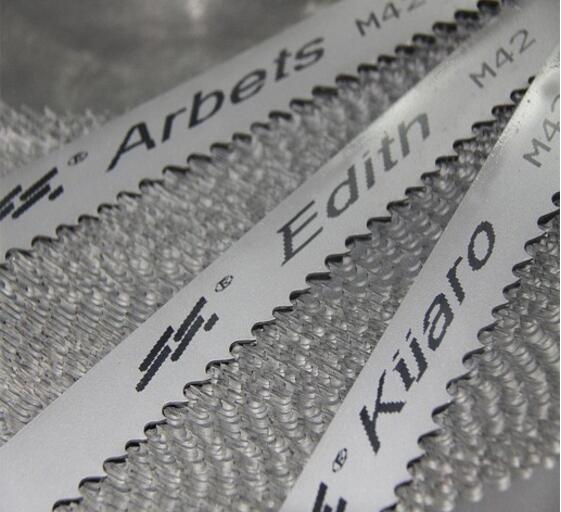

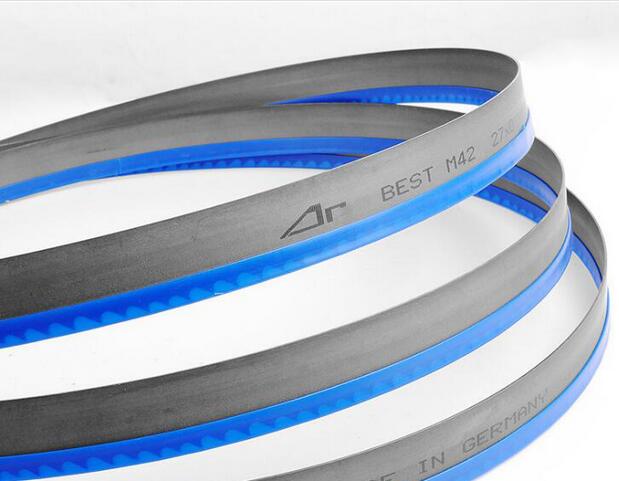

Low price M42 bimetal band saw blade

Bi-metal band saw blade with different tooth shapes from the width of the 27 mm to 67 mm. It include "LEXUS" and "Tenma", which cover different levels and can meet the demands of different areas.

High quality metal cutting band saw blades

M42 for the teeth and alloyed tool steel as the backing material ,are joined during the high energy laser welding process; resistance to war and fatigue.

Hot sales bimetal band saw blade

Samples need 1-2days, formal order according to your quantity;are produced with strict quality control system and the defective rate will be less than 0.2%.

High hardness stainless steel band saw blade

1.owing super high hardness,high red hardness and high wear resistance; 2.its shows excellent performance on cutting hard material,such as titanium; 3.the unique tooth shape design makes it have the excellent ability to chip; 4.the exquisite technology for the back material makes the band saw blades.

Horizontal Metal Cutting Band Saw Blade

1.ground mass is great, special spring steel and M42/M51 high-speed Cobalt steel; 2.the two parts of the blade body and the teeths are heat treated respectively; 3.the unfinished teeths are cylinder-shaped, And Welded to the blade body through high-energy.

Carbon Steel Bimetal Band Saw Blades

1.ground mass is great, special spring steel and M42/M51 high-speed Cobalt steel; 2.the two parts of the blade body and the teeths are heat treated respectively; 3.the unfinished teeths are cylinder-shaped, And Welded to the blade body through high-energy; 4.longer life, lower price.

High-class horizontal band saw blade

1.ground mass is great, special spring steel and M42/M51 high-speed Cobalt steel; 2.the two parts of the blade body and the teeths are heat treated respectively; 3.the unfinished teeths are cylinder-shaped, And Welded to the blade body through high-energy; 4.longer life, lower price.

Bimetal Band Saw Blade With Lower Price

1.ground mass is great, special spring steel and M42/M51 high-speed Cobalt steel; 2.the two parts of the blade body and the teeths are heat treated respectively; 3.the unfinished teeths are cylinder-shaped, And Welded to the blade body through high-energy; 4.longer life, lower price.

High-performance band saw blades

1.Special technology; 2.best quality &best price; 3.International standard pakcing.

HSS High Quality Band Saw Blade

1.Special technology ; 2.International Packing details ; 3.Best price .

M42 High Cobalt Bimetal Band Saw Blade

1.ground mass is great, special spring steel and M42/M51 high-speed Cobalt steel; 2.the two parts of the blade body and the teeths are heat treated respectively; 3.the unfinished teeths are cylinder-shaped, And Welded to the blade body through high-energy.

Bi-metal Band Saw Blades Wholesale

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so on.

Professional M42 Metal Band Saw Blade

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so on.

Strong Stability Metal Cutting Band Saw Blade

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so on.

High quality Heavy Duty Stationary Band Saw Blade

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so on.

Best selling band saw blade for cutting stainless steel

Can cutting ordinary steel ,stainless steel,carbon steel,all kinds of hard and soft wood ,etc;Strong stability and abrasive resistance.

Wood cutting band saw blade

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so on.

Tungsten Carbide Steel BandSaw Blade For Furniture

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so on.

customized length carbon band saw blade

Using top quality steel as the raw material such as 65Mn from home ,Sk85,SKS5,SKS51 from japan and alloy steel 1074 from Swiden,so that the finished products can be shaper and more wear-resistant.

Band saw using for kitchen cleaning sponges

1.Simple structure in linear type ,easy in installation and maintation; 2.pneumatic parts ,electric parts and operation parts; 3.High pressure double crank to control the die opening and closing.

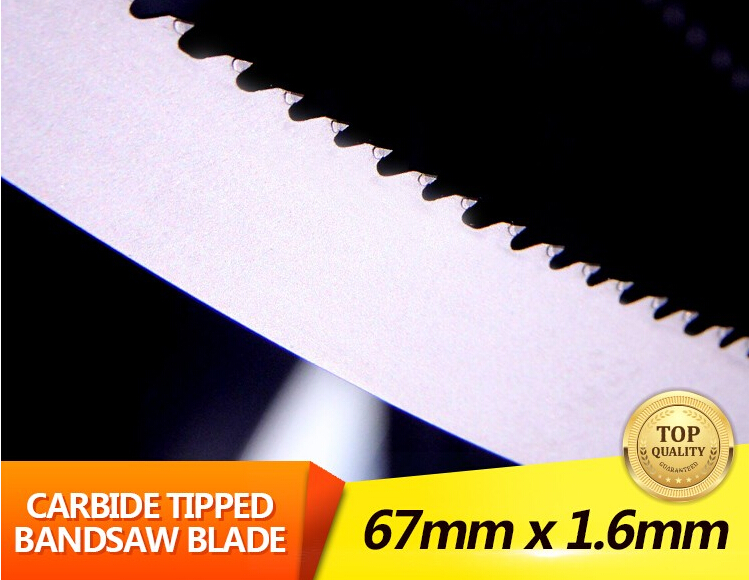

Carbide Tipped TCT Custom Band Saw Blades

perfect straightness,good stability,easy cutting and better trimming,is the most sffective and economical cutting toolfor the logs;Best cutting saw blade for the manufacturing with the high fatigue resistance at the high speed,low cost loss and good efficiency .

TCT band saw blade with carbide tip

Cutting some logs with large cross-section,different materials of band saw applies to different customer groups ,and we can adjust the hardness of band saw applying to the different using repuirments for the better tenacity and strong wear resistance.Performance with the best flatness .

carbide tip band saw blade for hard wood

1.To press and tense saw blade while repairing saws; 2.To keep the saw road by pressing and setting the saw teeth; 3.To choose the right saw teeth by the cutting material thickness; 4.To keep the saw blade sharp by grinding the teeth while in use.

manufacture splitting band saw blade with sharp edge

Our band knives can be manufactured with a number of different blade & tooth configurations;Each different edge geometry offers advantages to the cut quality & blade longevity when working with certain materials.

top quality different sizes band saw blade

Cutting some logs with large cross-section,different materials of band saw applies to different customer groups ,and we can adjust the hardness of band saw applying to the different using repuirments for the better tenacity and strong wear resistance.Performance with the best flatness .

custom size splitting band saw blade

can be manufactured with a number of different blade & tooth configurations; Each different edge geometry offers advantages to the cut quality & blade longevity when working with certain materials.

European type butcher cutting band saw blade

are made from quality material to ensure sanitary, sharpness and durability. These meet band saw blade are engineered for specific cutting needs ranging from precision fish slicing, meet slicing, bone cutting.

High quality meat cutting band saw blade

are engineered for specific cutting needs ranging from precision fish slicing, meet slicing, bone cutting. All meet cutting band saw blades are designed to lower cutting cost by generating efficient cuts while producing less waste.

Food grade meat band saw blade by coil

band saw blade are made from quality material to ensure sanitary, sharpness and durability. These meet band saw blade are engineered for specific cutting needs ranging from precision fish slicing, meet slicing, bone cutting.

25mm cheap TCT band saw cutting blade

TCT band saw blade provide high performance cutting to increase productivity and lower cost, these products will cut faster and last longer than any other band saw blade in a wide variety of sawing wood applications.

20mm tungsten carbide tip band saw blade

carbide tipped band saw blade provide high performance cutting to increase productivity and lower cost, these products will cut faster and last longer than any other band saw blade in a wide variety of sawing wood applications.

27mm hot sale carbide tip band saw blade

1.Size:0.9 x 27mm; 2.Blade material:C75; 3.Body HRC:46~48; 4.Carbide tip HRC:92.

35mm TCT band saw blade by welded

1.Size:0.9 x 35mm; 2.Blade material:C75; 3.HRC:46~48; 4.Advantage:Good performance, High efficiency.

Wood hardened teeth band saw blade by coil

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products’stability.

Hss M42 bandsaw machine use band saw blade

1.High abrasive resistance; 2.High red hardness; 2.unbreakable teeth; 2.excellent cutting performance.

Germany standard bimetal band saw blade

1.Size: 105mm-400mm; 2.Color:grey; 3.length:as request; 4.thickness:0.6mm-1.3mm; 5.working life:2 years.

High speed steel m42 bimetal band saw blade

bimetal band saw blades used of high alloy spring steel and HSS-M42 high-speed steel as raw materials;high wear resistance and high hardness.

M42 bi-metal band saw blade for cutting wood

1.Size:41*1.1*3/4 2.Color:grey 3.Tooth type:variable tooth 3/4

Band saw blades for cutting carbon steel pipe

1.great stablity.cutting steel, aluminum, iron bar, steel pipe, copper,lead,non-ferrous metal, etc; 2.High quality as well as Japanese; 3.suitable for steel material mass production; 4.high heat resistence and rust proof.

Good quality diamond tipped band saw blade

1.thickness:0.6mm-1.3mm; 2.standard:Germany; 3.working life:2 years 4.Dimensions: as your requirements 5.Weight: 5kg.

M42 Bimetal Band Saw Blade For Cutting Steel

1.High abrasive resistance; 2.High red hardness; 3.unbreakable teeth; 4.excellent cutting performance.

TCT Band Saw Blade For Cutting Granite

1.High speed steel M42 teeth; 2.Electron beam welding; 3.Deliver within 10days and according to the order quantity.

High abrasion resistance band saw blades

1.The frame saw blade welding with carbide and stellite two alloys; 2.has a particularly good corrosion resistance; 3.excellent oxidation resistance; 4.high abrasion resistance,superior toughness

High efficiency wood cutting band saw blade

This kind of bandsaw blade is also suitable for cutting purposes of all kinds of soft wood, oak, maple, walnut and other hard wood precessed in furniture factory and workshops.

Facory supplier horizontal band saw blades

It holds the advantage of high speed, extended blade life, high wear and fatigue resistance, its ability to perform high speed straight line cutting will bring massive improvement to your workpiece quality and efficiency.

High wear and fatigue resistance band saw blade

This kind of bandsaw blade is also suitable for cutting purposes of all kinds of soft wood, oak, maple, walnut and other hard wood precessed in furniture factory and workshops.

62 inch high speed band saw blade wholesale

It holds the advantage of high speed, extended blade life, high wear and fatigue resistance,its ability to perform high speed straight line cutting will bring massive improvement to your workpiece quality and efficiency.

High quality TCT band saw blades whosale

It holds the advantage of high speed, extended blade life, high wear and fatigue resistance, its ability to perform high speed straight line cutting will bring massive improvement to your workpiece quality and efficiency.

Vertical metal cutting band saw blade

A high cobalt M42 HSS cutting edge electron beam welded to a tough yet flexible alloy steel backing giving the blade and extremely hard cutting edge , while having a fully flexible back .

Rockwell aloy steel band saw wholesale

It holds the advantage of high speed, extended blade life, high wear and fatigue resistance, its ability to perform high speed straight line cutting will bring massive improvement to your workpiece quality and efficiency.

Wood Cutting TCT Band Saw Blade

1.The frame saw blade welding with carbide and stellite two alloys; 2.has a particularly good corrosion resistance; 3.excellent oxidation resistance; 4.high abrasion resistance,superior toughness.

High speed alloy steel saw blades

The saw teeth aer not easy to broken,wearing and twisting even in bad condition,with high stability when cutting.And the cutting surface is more clean and smooth with almost ZERO cutting accuracy.

Professional manufacturer bone saw blades

It have many advantage,such as extensive use,low price,OEM service,special technology,long using life,;Other sizes can be made according to customers' required;be designed for cutting both frozen meat ,fish.

High speed alloy steel band saw blade

It have many advantage,such as extensive use,low price,OEM service,special technology,long using life,;Other sizes can be made according to customers' required;be designed for cutting both frozen meat ,fish.

Commercial electric band saw blade

It have many advantage,such as extensive use,low price,OEM service,special technology,long using life,;Other sizes can be made according to customers' required;be designed for cutting both frozen meat ,fish.

Manufacturer lowest pirce band saw blade

professional manufacturer,best quality,lowest pirce,fast delivey;Packaged with cartons and secured by plywood or as per the customer's requirement.

Meat and bone cutting butcher's band saw blades

The size:16*0.56*4T;material:high speed alloy steel;thickness:0.50/0.56mm;teeth number:4;hardness teeth:65HRC.

1650mm food processing band saw blade

professional manufacturer,high quality,lowest pirce,fast delivey;Packed with cartons and secured by plywood or as per the customer's requirement.

High quality alloy steel band saw blade

1.The size:16*0.56*4T; 2.material:high speed alloy steel; 3.thickness:0.50/0.56mm; 4.teeth number:4; 5.hardness teeth:65HRC.

Harden tooth electric bone band saw blade

1.The size:16*0.56*4T; 2.material:high speed alloy steel; 3.thickness:0.50/0.56mm; 4.teeth number:4; 5.hardness teeth:65HRC.

Best Performance M42 Bimetal Band Saw Blade

1. high working effeciency; 2. reasonable price; 3. nice service consulting,selling,aftersells; 4. betweenφ105mm and φ800mm have good performance and high safety for laser welding.

High-Speed Steel Band Saw Blade

It suitable for almost all types of metal cutting in succession,Such as structural steel, weathering steel, alloy steel, bearing steel,stainless steel, heat-resistant steel, aluminum alloy, steel, etc.

Hot Selling Bimetal Band Saw Blade

Band saw tooth size is determined by the size and type of material to be cut and the desired finish. Select a pitch based on the charts below. Find material dimensions on bottom of chart and move up for appropriate teeth per inch.

High Working Effeciency Bimetal Band Saw Blade

Distinct advantages of our silent cores from D 200mm to D 1600mm include effectively reducing noise and outstanding performance, which make it a new generation environmental product, representing the development direction of diamond steel cores of cutting-edge technology.

High Quality Cut Metal Band Saw Blade

1.high working effeciency; 2.reasonable price; 3.nice service consulting,selling,aftersells; 4.betweenφ105mm and φ800mm have good performance and high safety for laser welding. The key technical indexes of such cores have been up to scratch of Europe and America.

Manufacturer directly sale metal band saw blades

Band saw blades can be cut and welded to any length. When ordering band saw blades you need to supply the following information:Length of blade,Width of blade,Tooth pitch (Teeth per Inch).

Metal Cutting Band Saw Blade With Reasonable Price

Mainly used for cutting various ferrous metal and non-ferrous metal;Suitable for viscous strong degree of copper, aluminum and other materials with low;High hardness material suitable for stainless steel,bearing steel,alloy steel;Sectional size larger workpieces.

Band Saw Blade For Cutting Stainless Steel

It suitable for almost all types of metal cutting in succession,Such as structural steel, weathering steel, alloy steel, bearing steel,stainless steel, heat-resistant steel, aluminum alloy, steel, etc.

1.1*34 mm M42 Bi-metal Band Saw Blade

Bi-metal band saw blades are made of imported M42 high speed steel for edge and spring steel for backer by means of a series of advanced equipment and technique processing such as electron beam welding and specific heat treatment, etc.

Smooth Section 27*0.9MM HSS Band Saw Blade

Direct selling factory,reasonable and competitive price;quality meets european standards;has many advantages,such as long working,high efficiency.

Good Cutting Performance M42 Band Saw Blade

1.high cutting precision, high vibration cutting job best; 2.not partial cut continuous cutting ability, cost-effectiveness; 3.large, cost-effective, good cutting performance. Very durable, durable than ordinary metal band saw blade two times.

1.1x34 mm M51 Bi-metal Band Saw Blade

1.high-speed cutting, smooth section; 2.wear resistance, fatigue resistance; 3.high cutting precision, high vibration cutting job best; 4.not partial cut continuous cutting ability, cost-effectiveness.

High Cutting Precision Band Saw Blade

1.long working life, do not pull teeth, not collapse teeth; 2.high-speed cutting, smooth section; 3.wear resistance, fatigue resistance; 4.high cutting precision, high vibration cutting job best; 5.not partial cut continuous cutting ability, cost-effectiveness.

Entire disk bi-metal band saw blade whosale

1.long working life, do not pull teeth, not collapse teeth; 2.high-speed cutting, smooth section; 3.wear resistance, fatigue resistance; 4.high cutting precision, high vibration cutting job best.

Longest operating life m42 Durable Saw Blades

mainly referring to the prong material is a high-performance high-speed steel or other steel material is a metal band saw cutting low alloy spring steel band saw blade, this blade widely use, it can be used with any type of band sawing machine.

High speed M51 HSS bi-metal band saw blades

1.Welding with R80/B313 and M51 HSS PM; 2.Longest operating life; 3.High speed cutting and smooth section; 4.Better wear resistance; 5.Greatest fatigue resistance.

High-performance M42 hss Bimetal Band Saw Blade

supporting the use of suitable for almost all types of continuous metal cutting, such as: structural steel, weathering steel, alloy steel, bearing steel, stainless steel, heat-resistant steel, aluminum, steel mold.

M51 HSS Bimetal Band Saw Blade

mainly referring to the prong material is a high-performance high-speed steel or other steel material is a metal band saw cutting low alloy spring steel band saw blade, this blade widely use, it can be used with any type of band sawing machine.

Hot Sale Metal Cutting Band Saw Blade

Materials feature blade saw is a double metal structure: B318 backing, fatigue strength; M42 tooth material, 8% cobalt content, tooth hardness HRC67-69.

Reasonable Price M42 Bimetal Band Saw Blade

1. High wear resistance and high red hardness; 2. Serrated not easy to break; 3. Long service life.

Long Life Band Saw Blade for Cutting Stainless Steel

mainly refers to the band saw blades with high speed steel or other high performance steel tooth and low alloy spring steel saw belt.

Customized Stainless Steel Band Saw Blade

widely used in deferent kinds of fields, which can be used with any type of band sawing machine, for almost all types of metal continuous sawing, such as: structural steel, weathering steel, alloy steel, bearing steel, stainless steel, heat-resistant steel, aluminum , tool steel, etc.

Good Performance Metal Cutting Band Saw Blade

1. Good stability,easy cutting and good trimming ; 2. Serrated easy to break; 3. High productivity in stainless steel cutting; 4. High speed and high heat resistance; 5. Professional manufacture.

Bi-metal Band Saw Blade For Metal Cutting

1. Good stability,easy cutting and good trimming ; 2. Serrated easy to break; 3. High productivity in stainless steel cutting; 4. High speed and high heat resistance; 5. Professional manufacture.

Energy Saving Band Saw Blade Wholesale

1. Good stability, easy cutting and good trimming; 2. Good durable, accurate flatness and perfect straightness; 3. High productivity in wood cutting.

Band Saw Blade With Low Consumption

1. Good stability, easy cutting and good trimming; 2. Good durable, accurate flatness and perfect straightness; 3. High productivity in wood cutting.

Factory Fashionable band saw blade

1. Good stability, easy cutting and good trimming; 2. Good durable, accurate flatness and perfect straightness; 3. High productivity in wood cutting.

2017 Practical saw balde for stone cutting

For a variety of models at home and abroad, Band Saw Blade can be customized according to customers' requirements;shipping according to customer's country, good types, weight and requested delivery time.

Commonly Used Carbide Band Saw Blade

Carbide Tipped band saw blade is the best grade in all series of bimetal band saw blade products;The teeth materials are made by the highest hardness Tungsten Carbide material;And our carbide tipped band saw blade production line is the most advanced equipments in the world.

Low Noise Band Saw Blade With Qual Tooth

equal tooth is suitable for cutting various materials;The teeth can reduce the vibration and noise when cutting;A variety of product types can ensure that you get the best performance when your application is.

High Speed Cutting M42 Band Saw Blade

Bi-metal Bandsaw Blades are made of imported M42 high speed steel for edge and spring steel for backer by means of a series of advanced equipment and technique processing such as electron beam welding and specific heat treatment, etc.

Long working M42 bi-metal band saw blade

Bi-metal Bandsaw Blades are made of imported M42 high speed steel for edge and spring steel for backer by means of a series of advanced equipment and technique processing such as electron beam welding and specific heat treatment, etc.

Lower Price Bi-metal Band Saw Blade

Direct selling factory,reasonable and competitive price;quality meets european standards;has many advantages,such as long working,high efficiency;provide OEM and ODM service.

Best quality bimetal band saw blade

the best quality match the previously defined quality standards,the special tooth geometry is resistant againist vibrations and heavy irregular mechanical strain arising with the metioned applications.

Sharp Cheap HSS band saw blade

1.Length: 93-1/2" or 2375mm; 2.Width: 1/2" or 13mm; 3.Thickness: 0.025" or 0.65mm; 4.Teeth: 4/6 tpi.

Manufacture Cutting Effect Band Saw Blade

1.Size: 93-1/2" x 1/2" x 0.025" x 14tpi or 2375*13*0.65*14tpi; 2.Length: 93-1/2" or 2375mm; 3.Width: 1/2" or 13mm; 4.Thickness: 0.025" or 0.65mm.

High efficiency metal cutting band saw blade

1.Length: 93-1/2" or 2375mm; 2.Width: 1/2" or 13mm; 3.Thickness: 0.025" or 0.65mm; 4.Teeth: 4/6 tpi.

M42 band saw blades for cutting metal

1.Size: 93-1/2" x 1/2" x 0.025" x 14tpi or 2375*13*0.65*14tpi; 2.Length: 93-1/2" or 2375mm; 3.Width: 1/2" or 13mm; 4.Thickness: 0.025" or 0.65mm.

Facory supplier horizontal band saw blades

It holds the advantage of high speed, extended blade life, high wear and fatigue resistance, its ability to perform high speed straight line cutting will bring massive improvement to your workpiece quality and efficiency.

62 inch carbide band saw blade

1.The frame saw blade welding with carbide and stellite two alloys; 2.has a particularly good corrosion resistance; 3.excellent oxidation resistance; 4.high abrasion resistance,superior toughness.

Vertical metal cutting band saw blade

The M42 Bimetal band saw blade should be used for cutting solid sections on a production basis, and bimetal band saw blade is particularly impressive on the more difficult to machine materials such as stainless steel , nimonic , titanium and nickel alloys.

Custom length band saw blade

Made in high quality carbon tool steel,with good sharp and high hardness of the tip and strong tenecity of the matrix ;It is economical and easy to cut the hard wood and some kinds of hard material .

Manufacture economical band saw blade

1.length is customized according to your requirements; 2.width:13mm/16mm/19mm etc; 3.thickness:0.56mm/0.65mm etc.

High hardness circular band saw blade

Made in high quality carbon tool steel,with good sharp and high hardness of the tip and strong tenecity of the matrix ;It is economical and easy to cut the hard wood and some kinds of hard material .

Good sharp band saw blade

Made in high quality carbon tool steel,with good sharp and high hardness of the tip and strong tenecity of the matrix ;It is economical and easy to cut the hard wood and some kinds of hard material .

High quality carbon band saw blade

Made in high quality carbon tool steel,with good sharp and high hardness of the tip and strong tenecity of the matrix;It is economical and easy to cut the hard wood and some kinds of hard material.

High Speed Cutting Band Saw Blade

1.excellent oxidation resistance; 2.high abrasion resistance,superior toughness; 3.suitable for cutting meat , cutting bone , cutting fish.

High-efficiency M42 metal cutting band saw blade

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products’stability.

High Quality Carbide Band Saw Blade

Band saw blade is aiming at the cutting for high hardness and strong obdurabilty material,such as stainless steel,too steel ect.it is applied the special design of saw teeth and chip conveyor technique.

Best Price M42 Bi-Metal Band Saw Blade

The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.Primarily used for cutting steel.

Manufacturer Bimetal Band Saw Blades

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth. The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

Promotion Alloy Steel Saw Blade For Metal Cutting

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products’stability.

Sharp Tube Circular Cutting Band Saw Blade

The saw teeth aer not easy to broken,wearing and twisting even in bad condition,with high stability when cutting.And the cutting surface is more clean and smooth with almost ZERO cutting accuracy.

Metal Cutting Alloy Band Saw Blade

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products’stability.

High quanlity bIimetal band saw blade

Two materials, high speed steel (HSS)for the teeth and alloyed tool steel as the backing material ,are joined during the high energy laser welding process.

Manufacturer M42 metal cutting band saw blade

Direct selling factory,reasonable and competitive price;quality meets european standards;has many advantages,such as long working,high efficiency;provide OEM and ODM service.

M51 band saw blade with different tooth shapes

The specially developed backing material ,alloyed with 4% chromium ,R80\B318 band saw blade ,has excellent machanical properties under dynamic loading;this welding process results in an optimal combination of materials with respect to saw blade resistance to war and fatigue.

Portable metal cutting band saw blade

1.Longest operating life; 2.High speed cutting and smooth section; 3.Better wear resistance; 4.Greatest fatigue resistance.

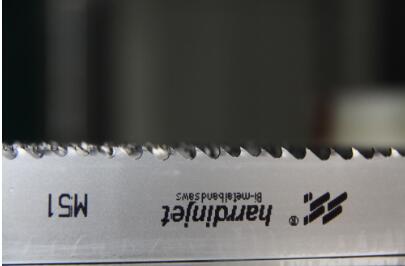

Auto feed metal cutting band saw blades

Harrdinjet uses high-performance R80/B318 backing material and high speed steel particulate matter tooth material;It is made by the advanced processing equipment and special heat treatment technology which was imported from Germany, Sweden, Italy etc.

High Speed Cutting Bi-metal band saw blade

1.Welding with R80/B313 and M51 HSS PM; 2.Longest operating life; 3.High speed cutting and smooth section; 4.Better wear resistance; 5.Greatest fatigue resistance.

M51 HSS Bi-metal band saw blades

Two materials, high speed steel (HSS)for the teeth and alloyed tool steel as the backing material ,are joined during the high energy laser welding process.

Tungsten tipped woodworking band saw blade

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products’stability.

Carbon steel cutting band saw blade

The saw teeth aer not easy to broken,wearing and twisting even in bad condition,with high stability when cutting.And the cutting surface is more clean and smooth.

Multi-Size Caride Band saw Blades

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products’stability.

Metal Cutting Band Saw Blade

Primarily used for cutting steel, this superior blade can also be used on nonferrous materials, handle solid and interrupt cutting(such as tubing), and provide lower cost per cut on the toughest sawing jobs.

High Efficiency Bimetal Band Saw blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth;The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

Band Saw Blade For Cutting Hard Alloy

1.Material : M42,alloy steel etc; 2.Width*Thickness: 13mm*0.6mm, 13*0.9mm,20mm*0.9mm, 27mm*0.9mm, 34mm*1.1mm,41*1.1mm, 41mm*1.3mm, 54mm*1.6mm, 67mm*1.6mm; 3.Length customized as your request or by coils.

High Speed Steel Bimetal Band Saw Blade

Primarily used for cutting steel, this superior blade can also be used on nonferrous materials, handle solid and interrupt cutting(such as tubing), and provide lower cost per cut on the toughest sawing jobs.

High Quality Bimetal Band Saw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth;The variable pitch design combines regular teeth of different pitches, gullet depths,and set angles for improved cutting and durability.

Tungsten Tipped Woodworking Band Saw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth;the variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

Bimetal Band Saw Blade With Competitive Price

Primarily used for cutting steel, this superior blade can also be used on nonferrous materials, handle solid and interrupt cutting(such as tubing), and provide lower cost per cut on the toughest sawing jobs.

Factory Metal Cutting Band Saw Blade

Primarily used for cutting steel, this superior blade can also be used on nonferrous materials, handle solid and interrupt cutting(such as tubing), and provide lower cost per cut on the toughest sawing jobs.

M42 High Cobalt Bimetal Band Saw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth;The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

Manufacturer Best Steel Cutting HSS Saw Blade

Useful on slow cutting off machines, automatic sawing machines for steel tubes, solids and profiles cutting;possibility of heat coating on all produced saw blades (tin, ticn, tialn), according to material to be worked.

High Performance Metal Cutting Band Saw Blade

Primarily used for cutting steel, this superior blade can also be used on nonferrous materials, handle solid and interrupt cutting(such as tubing), and provide lower cost per cut on the toughest sawing jobs.

Widely Used TCT Wood Band Saw Blade

TCT Wood band saw blade is widely used in deferent kinds of wood,which can be used with any type of band sawing machine. such as teak, gold-rimmed nanmu, soft wood, low and medium hard wood, hard wood, roeswood, hard wood, etc.

High Quality Bimetal Band Saw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth;the variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

Hot Sale Metal Band Saw Blade

<div>1.Back material: Spring steel from Germany and Austria; 2.Equipment: Main blade manufacturing line from Germany and Japan; 3.Technology: Professional engineer from Japan.</div>

High Quality Band Saw Blades

<div>With material from Germany and Austria,equipment from Germany and Japan,and advanced manufacturing technology,the quality of my bandsaw Blade has reached the advanced level of the world.</div>

High Efficiency Cheap Band Saw Blades

Direct selling factory,reasonable and competitive price;quality has reached the advanced level of the world. ;has many advantages,such as long working,high efficiency;provide OEM and ODM service.

Manufacture Bi-metal Band Saw Blades

Bi-metal band saw blades are made of imported M42 high speed steel for edge and spring steel for backer by means of a series of advanced equipment and technique processing such as electron beam welding and specific heat treatment,etc.

Band Saw Blade For Cut Various Ferrous

1.Back material: Spring steel from Germany and Austria; 2.Equipment: Main blade manufacturing line from Germany and Japan; 3.Technology: Professional engineer from Japan.

Competitive Price Good Hardness Band Saw Blade

1.Size: 27x0.9mm, 34x1.1mm, 41x1.3mm, 54x1.6mm, 67x1.6mm with various tooth type and tooth per inch; 2.Edge material: M42 high speed steel from Germany and Austria.

Factory Direct Selling Bi-Metal Bandsaw Blades

With material from Germany and Austria, equipment from Germany and Japan,and advanced manufacturing technology,the quality of my bandsaw Blade has reached the advanced level of the world.

High-Speed Steel Band saw Blades

Bandsaw blades are made of imported M42 high speed steel for edge and spring steel for backer by means of a series of advanced equipment and technique processing such as electron beam welding and specific heat treatment,etc.

19X0.9X5/8X2362 bi-metal band saw blade

The cutting surface of a toothed edge is composed of a row of pointed teeth;Common tooth variations include the number of teeth per inch and pitch pattern;They are used on ferrous and non-ferrous materials.

19X0.9X5/8X2060 bi-metal band saw blade

High speed steel tooth tips combined with flexible alloy steel backing material results in band saw blades that are the most cost effective choice for most metal sawing applications;5A wide variety of products are available to ensure optimal blade performance in your application.

27X0.9X3/4X3960 bi-metal bandsaw blades

The use of M-42 high-speed cobalt steel ensures high wear resistance of the band saw blade;The blade lends its broad application range to a unique heat treatment and effective use of the inherent material characteristics.

27X0.9X4/6X3280 metal band saw blades

The cutting surface of a toothed edge is composed of a row of pointed teeth;Common tooth variations include the number of teeth per inch and pitch pattern. They are used on ferrous and non-ferrous materials.

27X0.9X4/6X3215 metal band saw blades

The use of M-42 high-speed cobalt steel ensures high wear resistance of the band saw blade;The blade lends its broad application range to a unique heat treatment and effective use of the inherent material characteristics.

Alloy Steel Band Saw Blade

Saw teeth adopted in the double quenching technique,its special angular design can suit for cutting various materials with more sronger chip removal ability.

High Quality Metal Cutting Band Saw Blade

The saw teeth aer not easy to broken,wearing and twisting even in bad condition,with high stability when cutting.And the cutting surface is more clean and smooth with almost zero cutting accuracy.

High Durability Double Band Saw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth.The variable pitch design combines regular teeth of different pitches, gullet depths,and set angles for improved cutting and durability.

Customized Length M42 Bi-Metal Bandsaw Blades

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products'stability.

High Bending Resistance Metal Cutting Band Saw Blade

Primarily used for cutting steel,this superior blade can also be used on nonferrous materials,handle solid and interrupt cutting(such as tubing),and provide lower cost per cut on the toughest sawing jobs.

Sharp Bi-Metal Band Saw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth. The variable pitch design combines regular teeth of different pitches, gullet depths,and set angles for improved cutting and durability.Primarily used for cutting steel.

Professional M42 Bimetal Band Saw Balde

Saw blade could keep high-efficiency cutting about 70 hours with 7 square meter.normal saw blade’s average is 45 hours,best is 50 hours,only with 3-4 square meter.

16mm Stainless Steel Cutting Saw Blade

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products'stability.

Stainless Steel Cutting Band Saw Blade

The saw teeth aer not easy to broken,wearing and twisting even in bad condition,with high stability when cutting.And the cutting surface is more clean and smooth with almost ZERO cutting accuracy.

27*0.9mm Metal Cutting Band Saw Blades

Band saw blade is aiming at the cutting for high hardness and strong obdurabilty material,such as stainless steel,too steel ect.it is applied the special design of saw teeth and chip conveyor technique.

34*1.1mm Best Selling Metal Cutting Band Saw Balde

Saw blade could keep high-efficiency cutting about 70 hours with 7 square meter.normal saw blade's average is 45 hours,best is 50 hours,only with 3-4 square meter.

Unbreakable Teeth Bore-Half Shank Saw Blade

The band saw blade is designed for cutting both dry hard and soft wood, and also can be used to cut shaving board, wood fiber board and joinery panel.

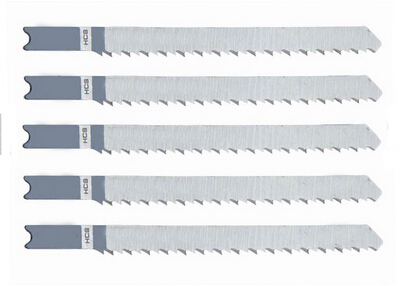

75mm Band Saw Blade Used For Metal

Material:HCS(65Mn)/ HSS/ BI-METAL;Package:Paper Card,Blister Card,Plastic Box,ect;Printing according to customers demand as OEM.

228 mm Customermized Printing Band Saw Blade

Special size and quality(ordinary quality and good quality) are available;various choice, humanized serving;lower price than rival in equal quality;high efficiency.

300 mm Band Saw Blade Used For Cutting Wood

It is a heavy-duty cutting tool, and you depend on it for excellent performance and longevity;it has many advance such as various choice,humanized serving lower price,high efficiency.

150 mm Reciprocating Band Saw Blade

Material is HCS(65Mn),HSS,BI-METAL;Printing according to customers demand as OEM;be designed for cutting both dry hard and soft wood, and also can be used to cut shaving board, wood fiber board and joinery panel.

27 X 0.9mm Metal Cutting Band Saw Blade

The special tooth geometry is resistant againist vibrations and heavy irregular mechanical strain arising with the metioned applications;the special size and TPI can also be produced upon request.

High Quality Metal Cutting Band Saw Blade

It's better to choose the bigger front tooth agnle when the stiffness for the procee system is poor or the power for the saw machines is shortage

M42 Band Saw Blade for Cutting Metal

Te best quality match the previously defined quality standards;the special size and TPI can also be produced upon request.

20X0.7mm Wood Cutting Band Saw Blade

Greatly strengthen the advantages of teeth hardness,red hardness, toughness and wear resistance; most suitable for cutting hard-wood materials.

M51 Band Saw Blade for Cutting Hard Steel

The best quality match the previously defined quality standards;the special tooth geometry is resistant againist vibrations and heavy irregular mechanical strain arising with the metioned applications.

51 sharp bimetal bandsaw blades

It is the new cutting material generation with advanced tooth geometry. Extreme resistance to heat and wear;greatly strengthen the advantages of teeth hardness, red hardness, toughness and wear resistance. It was specially created for work pieces which are difficult to cut.

M42 bi-metal bandsaw blades

Triple teeth set design. It is suitable for processing medium-sized and large-sized intractable materials;For Nickel-based alloy,titanium alloy,stainless steel ,tool steel,high temperature alloy,etc.

Various Size Stainless Steel Saw Blade

It is suitable for efficient cutting on stainless steel, mold steel, cast iron, bearing steel, titanium alloy,forged steel, hardened and tempered steel,high temperature alloy,etc.

M42 Bi-metal Band Saw Blades

1.For universal use and serial cuts. Generally used for small, medium-sized, large-sized solid materials cutting; 2.The tooth hardness is 68-69HRC(950HV-1000HV);

Carbide Bandsaw Blade for Cutting Stainless Steel

Triple teeth set design. It is suitable for processing medium-sized and large-sized intractable materials;for Nickel-based alloy,titanium alloy,stainless steel ,tool steel,high temperature alloy,etc;the tooth hardness is 79HRC (1600HV).

Smooth Metal Cutting Band Saw Blade

saw blade is a heavy-duty cutting tool, and you depend on it for sawing performance and longevity;It is possible to deliver band saw blades toothed,set;upply band saw blades welded to requested length or in packages(coins) of 25m or 50m or 100m.

High carbon steel strip band saw blade

It have many advantage,such as extensive use,low price,OEM service,special technology,long using life,;Other sizes can be made according to customers' required;be designed for cutting both frozen meat ,fish.

Stainless Steel Band Saw Blade for Cutting Wood

Application: The band saw blade is designed for cutting both dry hard and soft wood, and also can be used to cut shaving board, wood fiber board and joinery panel.Special technology;Low price;Long using life.

M42 BiMetal Band Saw Blade

High speed steel M42 teeth;65Mn back material;Electron beam welding;High abrasive resistance;excellent cutting performance.

High Quality Carbon Steel Band Saw Blade

It is a heavy-duty cutting tool, and you depend on it for excellent performance and longevity;Special size and quality(ordinary quality and good quality) are available;Various choice, humanized serving.

M42 BiMetal Bandsaw Blade

provide customers with products of excellent quality at a competitive price;the profile angle is bigger and the strength is higher, so it's suitable for cutting different kinds of the material.

41mmx1.3 Tungsten Carbide Saw Blade

The world's advanced oil quenching and continuous tempering technologies extremely improved the hardness of the tooth and the wear resistance of backing material,which made thoes two different material into perfect performance.

High Speed Bimetal Band Saw Blades

The equal teeth height and sharpness are better than traditional gear milling technology and the glossiness made for easily chip removal.

Hot Sale Carbon Band Saw Blades

Special heat-treatment technology solves the problems of knife bend and S bend.The straight band saw blade improves the quiet running property and the effect of saw cutting.

High Performance Metal Cutting Band Saw Blades

The precise upsetting technology improves the glossiness and geometric tolerance.Special design of cutting edge and angle suits different alloy material's saw cutting.

27mmx0.9 Bimetal Band Saw Blade

The equal teeth height and sharpness are better than traditional gear milling technology and the glossiness made for easily chip removal.

Hard M42 Bimetal Band Saw Blades

Special heat-treatment technology solves the problems of knife bend and S bend.The straight band saw blade improves the quiet running property and the effect of saw cutting.

27*0.9*3160 M42 bimetal cutting band saw blades

Application: High Nickel Chrome Alloys; Ti/Titanium Alloys; Heat Resistant steels; High Temperature Alloy Steels; Aluminum , and for high speed cutting of Aluminum Alloys; Other cutting application that M42 blade cannot be used.

67*1.6mm carbide band saw blades

The teeth materials are made by the highest hardness Tungsten Carbide material;no matter the accuracy process and smooth surface of the products,all meet international standards.

Hard carbide tipped band saw blade wholesale

Carbide tipped band saw blade is the best grade in all series of bimetal band saw blade products;the teeth materials are made by the highest hardness Tungsten Carbide material.

Hot sell sharp carbon steel band saw blade

Direct selling factory,reasonable and competitive price;no matter the accuracy process and smooth surface of the products,all meet international standards.

Factory Cheap Metal Cutting Band Saw Blade

Direct selling factory,reasonable and competitive price;quality meets european standards;has many advantages,such as long working,high efficiency;provide OEM and ODM service.

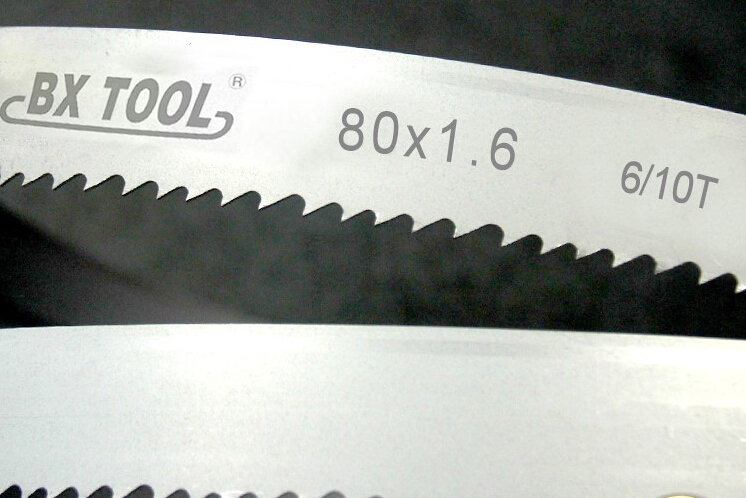

Manufacturer High Efficiency Bimetal Bandsaw Blades

The model number is 12.7mm-80mm;top quality for universal use;longer cutting life;more efficient,high speed cutting;OEM and ODM is available.

High Quality M42 Bimetal Band Saw Blade

direct selling factory,reasonable and competitive price;quality for universal use;longer cutting life;more efficient,high speed cutting.

M51 cutting stainless steel band saw blade

The size of band saw blade is 41mm1×3mm;top quality for universal use;longer cutting life;more efficient,high speed cutting.

M42 teeth tipped stainless steel band saw blade

Can make the band saw blades in coil condition or in weld loop;the length for coil or piece is according to customer requirements;some length per outer wooden case or carton.

M51 BI-METAL BAND SAW BLADE

Model Number: 12.7mm-80mm Type: Machine Blade Blade Material: HSS

M42 BI-METAL BAND SAW BLADE

Type:Machine Blade Blade Material:HSS Finishing:sandblased

M42 Bi metal band saw blade

M42 edge material (8%Co) Backing material High quality spring steel Laser welding

Double metal band saw blade

Custom processing is the brand MS, STARRETT type of M42 M51 MK Specification 3505 material M42 M51 was 3505 (mm) The width of 27 (mm) 4/6 3/4 2/3 5/8 8/12 pitch 6/10 (mm) range of metal prices, forging, casting, automobile, shipbuilding

Carbide tipped band saw blade

We can make the band saw blades in coil condition or in weld loop.Some length per outer wooden case or carton.The length for coil or piece is according to your requirements.

Tungsten Circular Carbide Saw Blade

Has a particularly good corrosion resistance, Excellent oxidation resistance, High abrasion resistance,superior toughness, Suitable for wood sawing / metel / alloy steel market.

High Resistant Tungsten Tip Saw Blades for aluminul cutting saw blade

Has a particularly good corrosion resistance, Excellent oxidation resistance, High abrasion resistance,superior toughness, Suitable for wood sawing / metel / alloy steel market.

Metal marble cutting tools disk saw bladecutting metal /marble

Professional technical and commercial service provided by experienced staff. Custom-made design is available, OEM&ODM are welcomed. Quick delivery.

Customized best sell tct timber factory band saw blade cutting metal

Has a particularly good corrosion resistance Excellent oxidation resistance, High abrasion resistance,superior toughness

HSS dmo5 circular Saw Blade for cutting Dubber

1)Has a particularly good corrosion resistance 2)Excellent oxidation resistance, 3)High abrasion resistance,superior toughness 4)Suitable for wood sawing / metel / alloy steel market

Band saw blade

Is the brand Starrett type 27*0.9 The material M42 is 3505 (mm) 27 (mm) width Pitch 2/3 3/4 (mm) thickness of 0.9 1.1 1.3 1.6 (mm) (mm) range of band sawing machine factory, forging factory, machinery plant, steel plant etc.

Customised Tooth Circular Saw Blade Blank with TiN -Coated

400mm X 32mm X 2mm Customised Tooth Circular Saw Blade Blank with TiN -Coated

Superior handheld industrial mini electric saw 1050W

Comfortable handle design for comfort and control 45 degree front bevel lock Continuous rating input: 1050 W

Superior handheld industrial mini electric saw 1050W

Comfortable handle design for comfort and control 45 degree front bevel lock Continuous rating input: 1050 W

16inch electric power cutting hand Saw 5402AL (1750W)

More stability and easy to control More durable and compact design A hardworking saw with the power to rip through most materials

Manufacturing high quality saw blade wood cutting mini electric saw

wood cutting mini electric saw 1. Professional manufacture. 2.Good quality with competitive price 3.OEM&ODM

Manufacturing high quality saw blade small electric saw

small electric saw 1. Professional manufacture. 2.Good quality with competitive price 3.OEM&ODM

High quality saw blade circular saw balde tct mini electric saw

mini electric saw 1. Professional manufacture. 2.Good quality with competitive price 3.OEM&ODM

Made in china saw blade SKS5 saw blade electric saw

electric saw 1)Suitable for 95% of wood sawing market 2)High quality ,Competitive price

High quality wood cutting mini electric saw of sawmill

csteel Edge: smooth cut off Advantage: high cutting ability and efficiency Size: can be customized Hardness: HV 560-640 Planeness: less 3‰ (width) Straightness: less 2mm

Low price circular TCT saw blade skill science electric saw

skill science electric saw 1)Suitable for 95% of wood sawing market 2)High quality ,Competitive price

- 1

- 2

- 3

- 4

- 5