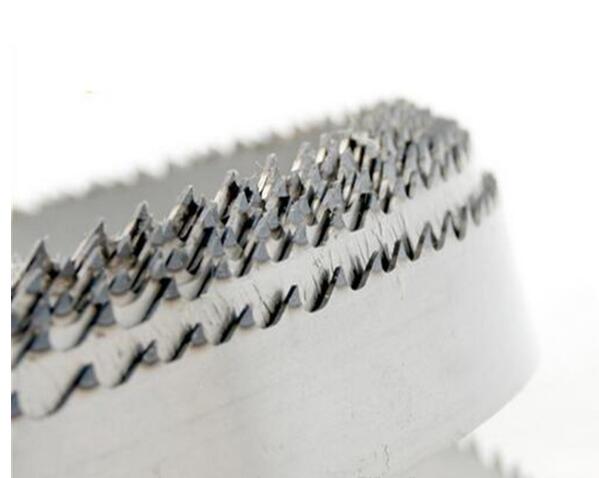

TCT band saw blades for cutting metal

1.High abrasive resistance; 2.High red hardness; 3.unbreakable teeth; 4.excellent cutting performance.

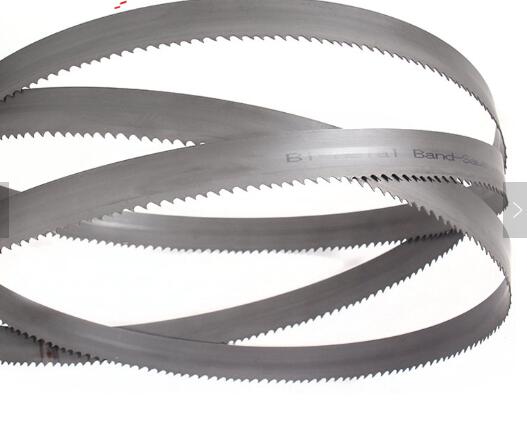

easy cutting cutting mental band saw blade

1.High abrasive resistance; 2.High red hardness; 3.unbreakable teeth; 4.excellent cutting performance.

good stability cutting metal band saw blades

1.High abrasive resistance; 2.High red hardness; 3.unbreakable teeth; 4.excellent cutting performance.

High quality metal cutting band saw blades

M42 for the teeth and alloyed tool steel as the backing material ,are joined during the high energy laser welding process; resistance to war and fatigue.

Horizontal Metal Cutting Band Saw Blade

1.ground mass is great, special spring steel and M42/M51 high-speed Cobalt steel; 2.the two parts of the blade body and the teeths are heat treated respectively; 3.the unfinished teeths are cylinder-shaped, And Welded to the blade body through high-energy.

Professional M42 Metal Band Saw Blade

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so on.

Strong Stability Metal Cutting Band Saw Blade

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so on.

High quality Heavy Duty Stationary Band Saw Blade

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so on.

Band saw using for kitchen cleaning sponges

1.Simple structure in linear type ,easy in installation and maintation; 2.pneumatic parts ,electric parts and operation parts; 3.High pressure double crank to control the die opening and closing.

Food grade meat band saw blade by coil

band saw blade are made from quality material to ensure sanitary, sharpness and durability. These meet band saw blade are engineered for specific cutting needs ranging from precision fish slicing, meet slicing, bone cutting.

Hss M42 bandsaw machine use band saw blade

1.High abrasive resistance; 2.High red hardness; 2.unbreakable teeth; 2.excellent cutting performance.

Facory supplier horizontal band saw blades

It holds the advantage of high speed, extended blade life, high wear and fatigue resistance, its ability to perform high speed straight line cutting will bring massive improvement to your workpiece quality and efficiency.

High wear and fatigue resistance band saw blade

This kind of bandsaw blade is also suitable for cutting purposes of all kinds of soft wood, oak, maple, walnut and other hard wood precessed in furniture factory and workshops.

62 inch high speed band saw blade wholesale

It holds the advantage of high speed, extended blade life, high wear and fatigue resistance,its ability to perform high speed straight line cutting will bring massive improvement to your workpiece quality and efficiency.

Vertical metal cutting band saw blade

A high cobalt M42 HSS cutting edge electron beam welded to a tough yet flexible alloy steel backing giving the blade and extremely hard cutting edge , while having a fully flexible back .

High speed alloy steel saw blades

The saw teeth aer not easy to broken,wearing and twisting even in bad condition,with high stability when cutting.And the cutting surface is more clean and smooth with almost ZERO cutting accuracy.

Professional manufacturer bone saw blades

It have many advantage,such as extensive use,low price,OEM service,special technology,long using life,;Other sizes can be made according to customers' required;be designed for cutting both frozen meat ,fish.

High speed alloy steel band saw blade

It have many advantage,such as extensive use,low price,OEM service,special technology,long using life,;Other sizes can be made according to customers' required;be designed for cutting both frozen meat ,fish.

Commercial electric band saw blade

It have many advantage,such as extensive use,low price,OEM service,special technology,long using life,;Other sizes can be made according to customers' required;be designed for cutting both frozen meat ,fish.

Manufacturer lowest pirce band saw blade

professional manufacturer,best quality,lowest pirce,fast delivey;Packaged with cartons and secured by plywood or as per the customer's requirement.

Meat and bone cutting butcher's band saw blades

The size:16*0.56*4T;material:high speed alloy steel;thickness:0.50/0.56mm;teeth number:4;hardness teeth:65HRC.

1650mm food processing band saw blade

professional manufacturer,high quality,lowest pirce,fast delivey;Packed with cartons and secured by plywood or as per the customer's requirement.

High quality alloy steel band saw blade

1.The size:16*0.56*4T; 2.material:high speed alloy steel; 3.thickness:0.50/0.56mm; 4.teeth number:4; 5.hardness teeth:65HRC.

Harden tooth electric bone band saw blade

1.The size:16*0.56*4T; 2.material:high speed alloy steel; 3.thickness:0.50/0.56mm; 4.teeth number:4; 5.hardness teeth:65HRC.

High Quality Cut Metal Band Saw Blade

1.high working effeciency; 2.reasonable price; 3.nice service consulting,selling,aftersells; 4.betweenφ105mm and φ800mm have good performance and high safety for laser welding. The key technical indexes of such cores have been up to scratch of Europe and America.

Manufacturer directly sale metal band saw blades

Band saw blades can be cut and welded to any length. When ordering band saw blades you need to supply the following information:Length of blade,Width of blade,Tooth pitch (Teeth per Inch).

Metal Cutting Band Saw Blade With Reasonable Price

Mainly used for cutting various ferrous metal and non-ferrous metal;Suitable for viscous strong degree of copper, aluminum and other materials with low;High hardness material suitable for stainless steel,bearing steel,alloy steel;Sectional size larger workpieces.

Hot Sale Metal Cutting Band Saw Blade

Materials feature blade saw is a double metal structure: B318 backing, fatigue strength; M42 tooth material, 8% cobalt content, tooth hardness HRC67-69.

Good Performance Metal Cutting Band Saw Blade

1. Good stability,easy cutting and good trimming ; 2. Serrated easy to break; 3. High productivity in stainless steel cutting; 4. High speed and high heat resistance; 5. Professional manufacture.

High efficiency metal cutting band saw blade

1.Length: 93-1/2" or 2375mm; 2.Width: 1/2" or 13mm; 3.Thickness: 0.025" or 0.65mm; 4.Teeth: 4/6 tpi.

M42 band saw blades for cutting metal

1.Size: 93-1/2" x 1/2" x 0.025" x 14tpi or 2375*13*0.65*14tpi; 2.Length: 93-1/2" or 2375mm; 3.Width: 1/2" or 13mm; 4.Thickness: 0.025" or 0.65mm.

Facory supplier horizontal band saw blades

It holds the advantage of high speed, extended blade life, high wear and fatigue resistance, its ability to perform high speed straight line cutting will bring massive improvement to your workpiece quality and efficiency.

Vertical metal cutting band saw blade

The M42 Bimetal band saw blade should be used for cutting solid sections on a production basis, and bimetal band saw blade is particularly impressive on the more difficult to machine materials such as stainless steel , nimonic , titanium and nickel alloys.

Manufacture economical band saw blade

1.length is customized according to your requirements; 2.width:13mm/16mm/19mm etc; 3.thickness:0.56mm/0.65mm etc.

High-efficiency M42 metal cutting band saw blade

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products’stability.

Promotion Alloy Steel Saw Blade For Metal Cutting

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products’stability.

Sharp Tube Circular Cutting Band Saw Blade

The saw teeth aer not easy to broken,wearing and twisting even in bad condition,with high stability when cutting.And the cutting surface is more clean and smooth with almost ZERO cutting accuracy.

Metal Cutting Alloy Band Saw Blade

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products’stability.

Manufacturer M42 metal cutting band saw blade

Direct selling factory,reasonable and competitive price;quality meets european standards;has many advantages,such as long working,high efficiency;provide OEM and ODM service.

Portable metal cutting band saw blade

1.Longest operating life; 2.High speed cutting and smooth section; 3.Better wear resistance; 4.Greatest fatigue resistance.

Auto feed metal cutting band saw blades

Harrdinjet uses high-performance R80/B318 backing material and high speed steel particulate matter tooth material;It is made by the advanced processing equipment and special heat treatment technology which was imported from Germany, Sweden, Italy etc.

Metal Cutting Band Saw Blade

Primarily used for cutting steel, this superior blade can also be used on nonferrous materials, handle solid and interrupt cutting(such as tubing), and provide lower cost per cut on the toughest sawing jobs.

Band Saw Blade For Cutting Hard Alloy

1.Material : M42,alloy steel etc; 2.Width*Thickness: 13mm*0.6mm, 13*0.9mm,20mm*0.9mm, 27mm*0.9mm, 34mm*1.1mm,41*1.1mm, 41mm*1.3mm, 54mm*1.6mm, 67mm*1.6mm; 3.Length customized as your request or by coils.

Factory Metal Cutting Band Saw Blade

Primarily used for cutting steel, this superior blade can also be used on nonferrous materials, handle solid and interrupt cutting(such as tubing), and provide lower cost per cut on the toughest sawing jobs.

High Performance Metal Cutting Band Saw Blade

Primarily used for cutting steel, this superior blade can also be used on nonferrous materials, handle solid and interrupt cutting(such as tubing), and provide lower cost per cut on the toughest sawing jobs.

Hot Sale Metal Band Saw Blade

<div>1.Back material: Spring steel from Germany and Austria; 2.Equipment: Main blade manufacturing line from Germany and Japan; 3.Technology: Professional engineer from Japan.</div>

High Efficiency Cheap Band Saw Blades

Direct selling factory,reasonable and competitive price;quality has reached the advanced level of the world. ;has many advantages,such as long working,high efficiency;provide OEM and ODM service.

Band Saw Blade For Cut Various Ferrous

1.Back material: Spring steel from Germany and Austria; 2.Equipment: Main blade manufacturing line from Germany and Japan; 3.Technology: Professional engineer from Japan.

High Quality Metal Cutting Band Saw Blade

The saw teeth aer not easy to broken,wearing and twisting even in bad condition,with high stability when cutting.And the cutting surface is more clean and smooth with almost zero cutting accuracy.

High Bending Resistance Metal Cutting Band Saw Blade

Primarily used for cutting steel,this superior blade can also be used on nonferrous materials,handle solid and interrupt cutting(such as tubing),and provide lower cost per cut on the toughest sawing jobs.

27*0.9mm Metal Cutting Band Saw Blades

Band saw blade is aiming at the cutting for high hardness and strong obdurabilty material,such as stainless steel,too steel ect.it is applied the special design of saw teeth and chip conveyor technique.

34*1.1mm Best Selling Metal Cutting Band Saw Balde

Saw blade could keep high-efficiency cutting about 70 hours with 7 square meter.normal saw blade's average is 45 hours,best is 50 hours,only with 3-4 square meter.

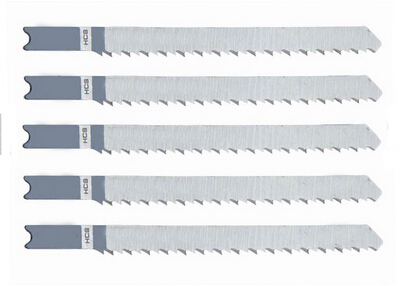

Unbreakable Teeth Bore-Half Shank Saw Blade

The band saw blade is designed for cutting both dry hard and soft wood, and also can be used to cut shaving board, wood fiber board and joinery panel.

75mm Band Saw Blade Used For Metal

Material:HCS(65Mn)/ HSS/ BI-METAL;Package:Paper Card,Blister Card,Plastic Box,ect;Printing according to customers demand as OEM.

228 mm Customermized Printing Band Saw Blade

Special size and quality(ordinary quality and good quality) are available;various choice, humanized serving;lower price than rival in equal quality;high efficiency.

27 X 0.9mm Metal Cutting Band Saw Blade

The special tooth geometry is resistant againist vibrations and heavy irregular mechanical strain arising with the metioned applications;the special size and TPI can also be produced upon request.

High Quality Metal Cutting Band Saw Blade

It's better to choose the bigger front tooth agnle when the stiffness for the procee system is poor or the power for the saw machines is shortage

M42 Band Saw Blade for Cutting Metal

Te best quality match the previously defined quality standards;the special size and TPI can also be produced upon request.

M51 Band Saw Blade for Cutting Hard Steel

The best quality match the previously defined quality standards;the special tooth geometry is resistant againist vibrations and heavy irregular mechanical strain arising with the metioned applications.

Smooth Metal Cutting Band Saw Blade

saw blade is a heavy-duty cutting tool, and you depend on it for sawing performance and longevity;It is possible to deliver band saw blades toothed,set;upply band saw blades welded to requested length or in packages(coins) of 25m or 50m or 100m.

High Performance Metal Cutting Band Saw Blades

The precise upsetting technology improves the glossiness and geometric tolerance.Special design of cutting edge and angle suits different alloy material's saw cutting.

Factory Cheap Metal Cutting Band Saw Blade

Direct selling factory,reasonable and competitive price;quality meets european standards;has many advantages,such as long working,high efficiency;provide OEM and ODM service.

High Resistant Tungsten Tip Saw Blades for aluminul cutting saw blade

Has a particularly good corrosion resistance, Excellent oxidation resistance, High abrasion resistance,superior toughness, Suitable for wood sawing / metel / alloy steel market.

Metal marble cutting tools disk saw bladecutting metal /marble

Professional technical and commercial service provided by experienced staff. Custom-made design is available, OEM&ODM are welcomed. Quick delivery.

Customized best sell tct timber factory band saw blade cutting metal

Has a particularly good corrosion resistance Excellent oxidation resistance, High abrasion resistance,superior toughness

HSS dmo5 circular Saw Blade for cutting Dubber

1)Has a particularly good corrosion resistance 2)Excellent oxidation resistance, 3)High abrasion resistance,superior toughness 4)Suitable for wood sawing / metel / alloy steel market

- 1

- 2

- 3

- 4

- 5