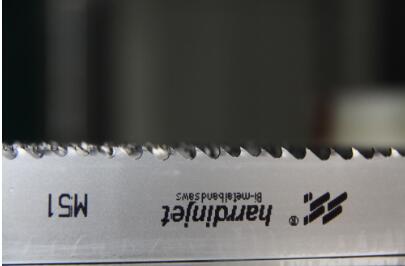

wear-resistance m42 bimetal band saw blade

M42 for the teeth and alloyed tool steel as the backing material ,are joined during the high energy laser welding process.

manufacturer Latest price band saw blade

Bi-metal Bandsaw Blades are made of imported M42 high speed steel for edge and spring steel for backer by means of a series of advanced equipment and technique processing such as electron beam welding and specific heat treatment, etc.

Low price M42 bimetal band saw blade

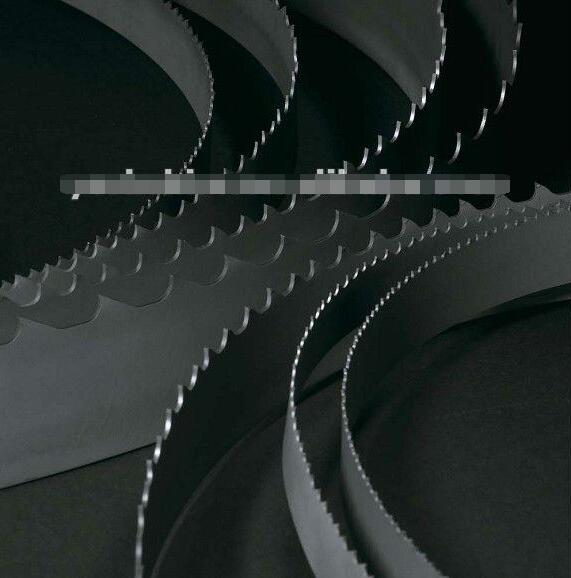

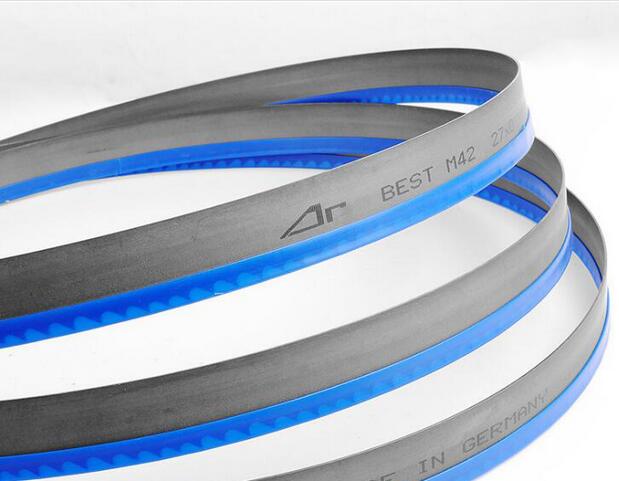

Bi-metal band saw blade with different tooth shapes from the width of the 27 mm to 67 mm. It include "LEXUS" and "Tenma", which cover different levels and can meet the demands of different areas.

Hot sales bimetal band saw blade

Samples need 1-2days, formal order according to your quantity;are produced with strict quality control system and the defective rate will be less than 0.2%.

Carbon Steel Bimetal Band Saw Blades

1.ground mass is great, special spring steel and M42/M51 high-speed Cobalt steel; 2.the two parts of the blade body and the teeths are heat treated respectively; 3.the unfinished teeths are cylinder-shaped, And Welded to the blade body through high-energy; 4.longer life, lower price.

High-class horizontal band saw blade

1.ground mass is great, special spring steel and M42/M51 high-speed Cobalt steel; 2.the two parts of the blade body and the teeths are heat treated respectively; 3.the unfinished teeths are cylinder-shaped, And Welded to the blade body through high-energy; 4.longer life, lower price.

Bimetal Band Saw Blade With Lower Price

1.ground mass is great, special spring steel and M42/M51 high-speed Cobalt steel; 2.the two parts of the blade body and the teeths are heat treated respectively; 3.the unfinished teeths are cylinder-shaped, And Welded to the blade body through high-energy; 4.longer life, lower price.

High-performance band saw blades

1.Special technology; 2.best quality &best price; 3.International standard pakcing.

HSS High Quality Band Saw Blade

1.Special technology ; 2.International Packing details ; 3.Best price .

M42 High Cobalt Bimetal Band Saw Blade

1.ground mass is great, special spring steel and M42/M51 high-speed Cobalt steel; 2.the two parts of the blade body and the teeths are heat treated respectively; 3.the unfinished teeths are cylinder-shaped, And Welded to the blade body through high-energy.

Bi-metal Band Saw Blades Wholesale

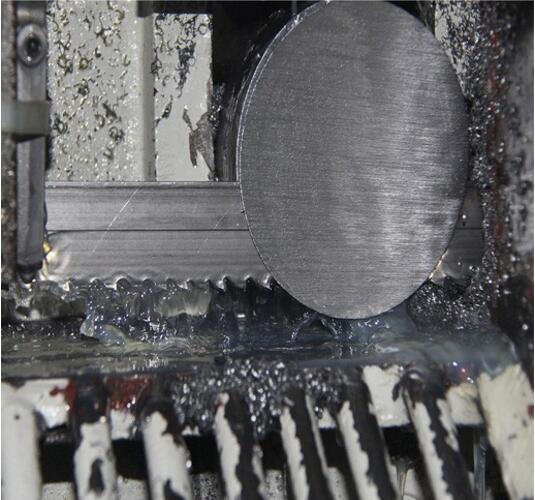

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so on.

25mm cheap TCT band saw cutting blade

TCT band saw blade provide high performance cutting to increase productivity and lower cost, these products will cut faster and last longer than any other band saw blade in a wide variety of sawing wood applications.

Germany standard bimetal band saw blade

1.Size: 105mm-400mm; 2.Color:grey; 3.length:as request; 4.thickness:0.6mm-1.3mm; 5.working life:2 years.

High speed steel m42 bimetal band saw blade

bimetal band saw blades used of high alloy spring steel and HSS-M42 high-speed steel as raw materials;high wear resistance and high hardness.

M42 bi-metal band saw blade for cutting wood

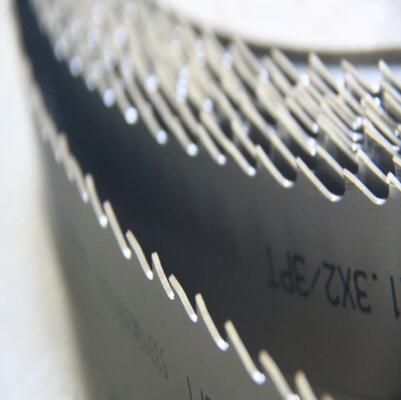

1.Size:41*1.1*3/4 2.Color:grey 3.Tooth type:variable tooth 3/4

M42 Bimetal Band Saw Blade For Cutting Steel

1.High abrasive resistance; 2.High red hardness; 3.unbreakable teeth; 4.excellent cutting performance.

TCT Band Saw Blade For Cutting Granite

1.High speed steel M42 teeth; 2.Electron beam welding; 3.Deliver within 10days and according to the order quantity.

Best Performance M42 Bimetal Band Saw Blade

1. high working effeciency; 2. reasonable price; 3. nice service consulting,selling,aftersells; 4. betweenφ105mm and φ800mm have good performance and high safety for laser welding.

Hot Selling Bimetal Band Saw Blade

Band saw tooth size is determined by the size and type of material to be cut and the desired finish. Select a pitch based on the charts below. Find material dimensions on bottom of chart and move up for appropriate teeth per inch.

High Working Effeciency Bimetal Band Saw Blade

Distinct advantages of our silent cores from D 200mm to D 1600mm include effectively reducing noise and outstanding performance, which make it a new generation environmental product, representing the development direction of diamond steel cores of cutting-edge technology.

1.1*34 mm M42 Bi-metal Band Saw Blade

Bi-metal band saw blades are made of imported M42 high speed steel for edge and spring steel for backer by means of a series of advanced equipment and technique processing such as electron beam welding and specific heat treatment, etc.

Smooth Section 27*0.9MM HSS Band Saw Blade

Direct selling factory,reasonable and competitive price;quality meets european standards;has many advantages,such as long working,high efficiency.

Good Cutting Performance M42 Band Saw Blade

1.high cutting precision, high vibration cutting job best; 2.not partial cut continuous cutting ability, cost-effectiveness; 3.large, cost-effective, good cutting performance. Very durable, durable than ordinary metal band saw blade two times.

1.1x34 mm M51 Bi-metal Band Saw Blade

1.high-speed cutting, smooth section; 2.wear resistance, fatigue resistance; 3.high cutting precision, high vibration cutting job best; 4.not partial cut continuous cutting ability, cost-effectiveness.

High Cutting Precision Band Saw Blade

1.long working life, do not pull teeth, not collapse teeth; 2.high-speed cutting, smooth section; 3.wear resistance, fatigue resistance; 4.high cutting precision, high vibration cutting job best; 5.not partial cut continuous cutting ability, cost-effectiveness.

Entire disk bi-metal band saw blade whosale

1.long working life, do not pull teeth, not collapse teeth; 2.high-speed cutting, smooth section; 3.wear resistance, fatigue resistance; 4.high cutting precision, high vibration cutting job best.

Longest operating life m42 Durable Saw Blades

mainly referring to the prong material is a high-performance high-speed steel or other steel material is a metal band saw cutting low alloy spring steel band saw blade, this blade widely use, it can be used with any type of band sawing machine.

High speed M51 HSS bi-metal band saw blades

1.Welding with R80/B313 and M51 HSS PM; 2.Longest operating life; 3.High speed cutting and smooth section; 4.Better wear resistance; 5.Greatest fatigue resistance.

High-performance M42 hss Bimetal Band Saw Blade

supporting the use of suitable for almost all types of continuous metal cutting, such as: structural steel, weathering steel, alloy steel, bearing steel, stainless steel, heat-resistant steel, aluminum, steel mold.

M51 HSS Bimetal Band Saw Blade

mainly referring to the prong material is a high-performance high-speed steel or other steel material is a metal band saw cutting low alloy spring steel band saw blade, this blade widely use, it can be used with any type of band sawing machine.

Reasonable Price M42 Bimetal Band Saw Blade

1. High wear resistance and high red hardness; 2. Serrated not easy to break; 3. Long service life.

Bi-metal Band Saw Blade For Metal Cutting

1. Good stability,easy cutting and good trimming ; 2. Serrated easy to break; 3. High productivity in stainless steel cutting; 4. High speed and high heat resistance; 5. Professional manufacture.

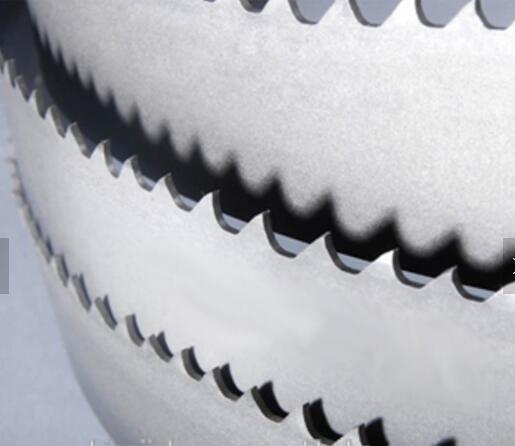

Low Noise Band Saw Blade With Qual Tooth

equal tooth is suitable for cutting various materials;The teeth can reduce the vibration and noise when cutting;A variety of product types can ensure that you get the best performance when your application is.

High Speed Cutting M42 Band Saw Blade

Bi-metal Bandsaw Blades are made of imported M42 high speed steel for edge and spring steel for backer by means of a series of advanced equipment and technique processing such as electron beam welding and specific heat treatment, etc.

Long working M42 bi-metal band saw blade

Bi-metal Bandsaw Blades are made of imported M42 high speed steel for edge and spring steel for backer by means of a series of advanced equipment and technique processing such as electron beam welding and specific heat treatment, etc.

Lower Price Bi-metal Band Saw Blade

Direct selling factory,reasonable and competitive price;quality meets european standards;has many advantages,such as long working,high efficiency;provide OEM and ODM service.

Best quality bimetal band saw blade

the best quality match the previously defined quality standards,the special tooth geometry is resistant againist vibrations and heavy irregular mechanical strain arising with the metioned applications.

Sharp Cheap HSS band saw blade

1.Length: 93-1/2" or 2375mm; 2.Width: 1/2" or 13mm; 3.Thickness: 0.025" or 0.65mm; 4.Teeth: 4/6 tpi.

Manufacture Cutting Effect Band Saw Blade

1.Size: 93-1/2" x 1/2" x 0.025" x 14tpi or 2375*13*0.65*14tpi; 2.Length: 93-1/2" or 2375mm; 3.Width: 1/2" or 13mm; 4.Thickness: 0.025" or 0.65mm.

Best Price M42 Bi-Metal Band Saw Blade

The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.Primarily used for cutting steel.

Manufacturer Bimetal Band Saw Blades

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth. The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

High quanlity bIimetal band saw blade

Two materials, high speed steel (HSS)for the teeth and alloyed tool steel as the backing material ,are joined during the high energy laser welding process.

M51 band saw blade with different tooth shapes

The specially developed backing material ,alloyed with 4% chromium ,R80\B318 band saw blade ,has excellent machanical properties under dynamic loading;this welding process results in an optimal combination of materials with respect to saw blade resistance to war and fatigue.

High Speed Cutting Bi-metal band saw blade

1.Welding with R80/B313 and M51 HSS PM; 2.Longest operating life; 3.High speed cutting and smooth section; 4.Better wear resistance; 5.Greatest fatigue resistance.

M51 HSS Bi-metal band saw blades

Two materials, high speed steel (HSS)for the teeth and alloyed tool steel as the backing material ,are joined during the high energy laser welding process.

High Efficiency Bimetal Band Saw blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth;The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

High Speed Steel Bimetal Band Saw Blade

Primarily used for cutting steel, this superior blade can also be used on nonferrous materials, handle solid and interrupt cutting(such as tubing), and provide lower cost per cut on the toughest sawing jobs.

High Quality Bimetal Band Saw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth;The variable pitch design combines regular teeth of different pitches, gullet depths,and set angles for improved cutting and durability.

Tungsten Tipped Woodworking Band Saw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth;the variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

Bimetal Band Saw Blade With Competitive Price

Primarily used for cutting steel, this superior blade can also be used on nonferrous materials, handle solid and interrupt cutting(such as tubing), and provide lower cost per cut on the toughest sawing jobs.

M42 High Cobalt Bimetal Band Saw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth;The variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

Widely Used TCT Wood Band Saw Blade

TCT Wood band saw blade is widely used in deferent kinds of wood,which can be used with any type of band sawing machine. such as teak, gold-rimmed nanmu, soft wood, low and medium hard wood, hard wood, roeswood, hard wood, etc.

High Quality Bimetal Band Saw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth;the variable pitch design combines regular teeth of different pitches, gullet depths, and set angles for improved cutting and durability.

High Quality Band Saw Blades

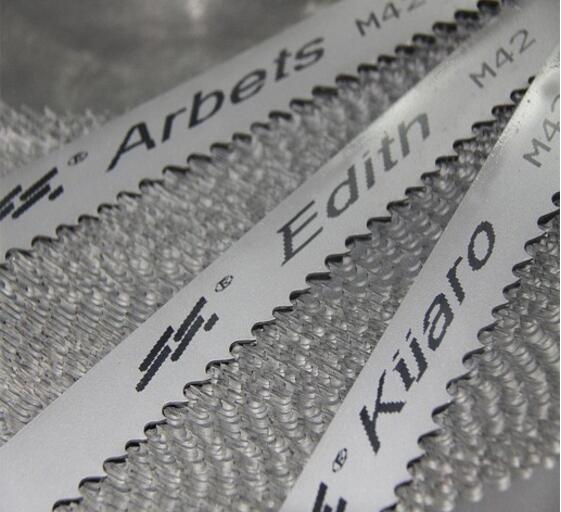

<div>With material from Germany and Austria,equipment from Germany and Japan,and advanced manufacturing technology,the quality of my bandsaw Blade has reached the advanced level of the world.</div>

Manufacture Bi-metal Band Saw Blades

Bi-metal band saw blades are made of imported M42 high speed steel for edge and spring steel for backer by means of a series of advanced equipment and technique processing such as electron beam welding and specific heat treatment,etc.

Competitive Price Good Hardness Band Saw Blade

1.Size: 27x0.9mm, 34x1.1mm, 41x1.3mm, 54x1.6mm, 67x1.6mm with various tooth type and tooth per inch; 2.Edge material: M42 high speed steel from Germany and Austria.

Factory Direct Selling Bi-Metal Bandsaw Blades

With material from Germany and Austria, equipment from Germany and Japan,and advanced manufacturing technology,the quality of my bandsaw Blade has reached the advanced level of the world.

19X0.9X5/8X2362 bi-metal band saw blade

The cutting surface of a toothed edge is composed of a row of pointed teeth;Common tooth variations include the number of teeth per inch and pitch pattern;They are used on ferrous and non-ferrous materials.

19X0.9X5/8X2060 bi-metal band saw blade

High speed steel tooth tips combined with flexible alloy steel backing material results in band saw blades that are the most cost effective choice for most metal sawing applications;5A wide variety of products are available to ensure optimal blade performance in your application.

27X0.9X3/4X3960 bi-metal bandsaw blades

The use of M-42 high-speed cobalt steel ensures high wear resistance of the band saw blade;The blade lends its broad application range to a unique heat treatment and effective use of the inherent material characteristics.

27X0.9X4/6X3280 metal band saw blades

The cutting surface of a toothed edge is composed of a row of pointed teeth;Common tooth variations include the number of teeth per inch and pitch pattern. They are used on ferrous and non-ferrous materials.

27X0.9X4/6X3215 metal band saw blades

The use of M-42 high-speed cobalt steel ensures high wear resistance of the band saw blade;The blade lends its broad application range to a unique heat treatment and effective use of the inherent material characteristics.

High Durability Double Band Saw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth.The variable pitch design combines regular teeth of different pitches, gullet depths,and set angles for improved cutting and durability.

Customized Length M42 Bi-Metal Bandsaw Blades

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products'stability.

Sharp Bi-Metal Band Saw Blade

Bimetal band saw blade is welded by an electron beam under high vacuum to attach a strip of high-speed M42(8% Co) tooth. The variable pitch design combines regular teeth of different pitches, gullet depths,and set angles for improved cutting and durability.Primarily used for cutting steel.

Professional M42 Bimetal Band Saw Balde

Saw blade could keep high-efficiency cutting about 70 hours with 7 square meter.normal saw blade’s average is 45 hours,best is 50 hours,only with 3-4 square meter.

51 sharp bimetal bandsaw blades

It is the new cutting material generation with advanced tooth geometry. Extreme resistance to heat and wear;greatly strengthen the advantages of teeth hardness, red hardness, toughness and wear resistance. It was specially created for work pieces which are difficult to cut.

M42 bi-metal bandsaw blades

Triple teeth set design. It is suitable for processing medium-sized and large-sized intractable materials;For Nickel-based alloy,titanium alloy,stainless steel ,tool steel,high temperature alloy,etc.

M42 Bi-metal Band Saw Blades

1.For universal use and serial cuts. Generally used for small, medium-sized, large-sized solid materials cutting; 2.The tooth hardness is 68-69HRC(950HV-1000HV);

M42 BiMetal Band Saw Blade

High speed steel M42 teeth;65Mn back material;Electron beam welding;High abrasive resistance;excellent cutting performance.

M42 BiMetal Bandsaw Blade

provide customers with products of excellent quality at a competitive price;the profile angle is bigger and the strength is higher, so it's suitable for cutting different kinds of the material.

High Speed Bimetal Band Saw Blades

The equal teeth height and sharpness are better than traditional gear milling technology and the glossiness made for easily chip removal.

27mmx0.9 Bimetal Band Saw Blade

The equal teeth height and sharpness are better than traditional gear milling technology and the glossiness made for easily chip removal.

Hard M42 Bimetal Band Saw Blades

Special heat-treatment technology solves the problems of knife bend and S bend.The straight band saw blade improves the quiet running property and the effect of saw cutting.

27*0.9*3160 M42 bimetal cutting band saw blades

Application: High Nickel Chrome Alloys; Ti/Titanium Alloys; Heat Resistant steels; High Temperature Alloy Steels; Aluminum , and for high speed cutting of Aluminum Alloys; Other cutting application that M42 blade cannot be used.

Manufacturer High Efficiency Bimetal Bandsaw Blades

The model number is 12.7mm-80mm;top quality for universal use;longer cutting life;more efficient,high speed cutting;OEM and ODM is available.

High Quality M42 Bimetal Band Saw Blade

direct selling factory,reasonable and competitive price;quality for universal use;longer cutting life;more efficient,high speed cutting.

M51 BI-METAL BAND SAW BLADE

Model Number: 12.7mm-80mm Type: Machine Blade Blade Material: HSS

M42 BI-METAL BAND SAW BLADE

Type:Machine Blade Blade Material:HSS Finishing:sandblased

M42 Bi metal band saw blade

M42 edge material (8%Co) Backing material High quality spring steel Laser welding

Double metal band saw blade

Custom processing is the brand MS, STARRETT type of M42 M51 MK Specification 3505 material M42 M51 was 3505 (mm) The width of 27 (mm) 4/6 3/4 2/3 5/8 8/12 pitch 6/10 (mm) range of metal prices, forging, casting, automobile, shipbuilding

- 1

- 2

- 3

- 4

- 5