Wood cutting band saw blade

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so on.

Tungsten Carbide Steel BandSaw Blade For Furniture

Application of band saw blade is very broad, general used in machinery industry, machinery manufacturing, automotive service industry, metal mining industry, and so on.

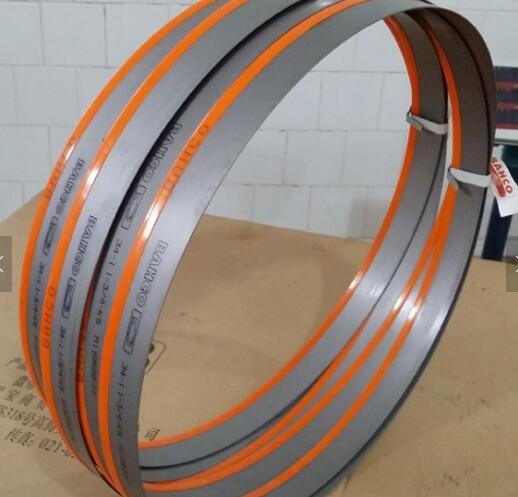

customized length carbon band saw blade

Using top quality steel as the raw material such as 65Mn from home ,Sk85,SKS5,SKS51 from japan and alloy steel 1074 from Swiden,so that the finished products can be shaper and more wear-resistant.

Carbide Tipped TCT Custom Band Saw Blades

perfect straightness,good stability,easy cutting and better trimming,is the most sffective and economical cutting toolfor the logs;Best cutting saw blade for the manufacturing with the high fatigue resistance at the high speed,low cost loss and good efficiency .

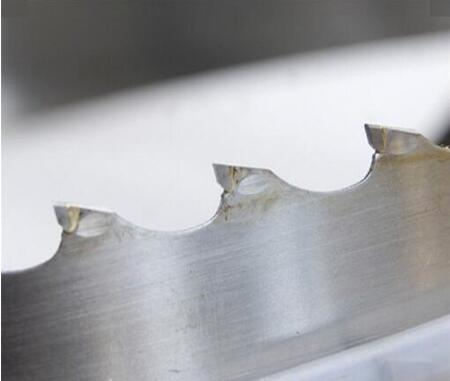

TCT band saw blade with carbide tip

Cutting some logs with large cross-section,different materials of band saw applies to different customer groups ,and we can adjust the hardness of band saw applying to the different using repuirments for the better tenacity and strong wear resistance.Performance with the best flatness .

carbide tip band saw blade for hard wood

1.To press and tense saw blade while repairing saws; 2.To keep the saw road by pressing and setting the saw teeth; 3.To choose the right saw teeth by the cutting material thickness; 4.To keep the saw blade sharp by grinding the teeth while in use.

manufacture splitting band saw blade with sharp edge

Our band knives can be manufactured with a number of different blade & tooth configurations;Each different edge geometry offers advantages to the cut quality & blade longevity when working with certain materials.

European type butcher cutting band saw blade

are made from quality material to ensure sanitary, sharpness and durability. These meet band saw blade are engineered for specific cutting needs ranging from precision fish slicing, meet slicing, bone cutting.

20mm tungsten carbide tip band saw blade

carbide tipped band saw blade provide high performance cutting to increase productivity and lower cost, these products will cut faster and last longer than any other band saw blade in a wide variety of sawing wood applications.

27mm hot sale carbide tip band saw blade

1.Size:0.9 x 27mm; 2.Blade material:C75; 3.Body HRC:46~48; 4.Carbide tip HRC:92.

Band saw blades for cutting carbon steel pipe

1.great stablity.cutting steel, aluminum, iron bar, steel pipe, copper,lead,non-ferrous metal, etc; 2.High quality as well as Japanese; 3.suitable for steel material mass production; 4.high heat resistence and rust proof.

High abrasion resistance band saw blades

1.The frame saw blade welding with carbide and stellite two alloys; 2.has a particularly good corrosion resistance; 3.excellent oxidation resistance; 4.high abrasion resistance,superior toughness

High efficiency wood cutting band saw blade

This kind of bandsaw blade is also suitable for cutting purposes of all kinds of soft wood, oak, maple, walnut and other hard wood precessed in furniture factory and workshops.

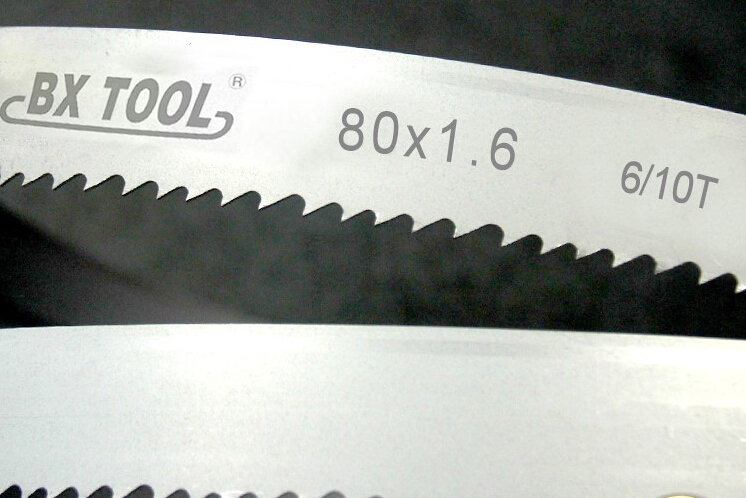

High quality TCT band saw blades whosale

It holds the advantage of high speed, extended blade life, high wear and fatigue resistance, its ability to perform high speed straight line cutting will bring massive improvement to your workpiece quality and efficiency.

Rockwell aloy steel band saw wholesale

It holds the advantage of high speed, extended blade life, high wear and fatigue resistance, its ability to perform high speed straight line cutting will bring massive improvement to your workpiece quality and efficiency.

Wood Cutting TCT Band Saw Blade

1.The frame saw blade welding with carbide and stellite two alloys; 2.has a particularly good corrosion resistance; 3.excellent oxidation resistance; 4.high abrasion resistance,superior toughness.

Energy Saving Band Saw Blade Wholesale

1. Good stability, easy cutting and good trimming; 2. Good durable, accurate flatness and perfect straightness; 3. High productivity in wood cutting.

Band Saw Blade With Low Consumption

1. Good stability, easy cutting and good trimming; 2. Good durable, accurate flatness and perfect straightness; 3. High productivity in wood cutting.

Factory Fashionable band saw blade

1. Good stability, easy cutting and good trimming; 2. Good durable, accurate flatness and perfect straightness; 3. High productivity in wood cutting.

2017 Practical saw balde for stone cutting

For a variety of models at home and abroad, Band Saw Blade can be customized according to customers' requirements;shipping according to customer's country, good types, weight and requested delivery time.

Commonly Used Carbide Band Saw Blade

Carbide Tipped band saw blade is the best grade in all series of bimetal band saw blade products;The teeth materials are made by the highest hardness Tungsten Carbide material;And our carbide tipped band saw blade production line is the most advanced equipments in the world.

62 inch carbide band saw blade

1.The frame saw blade welding with carbide and stellite two alloys; 2.has a particularly good corrosion resistance; 3.excellent oxidation resistance; 4.high abrasion resistance,superior toughness.

Custom length band saw blade

Made in high quality carbon tool steel,with good sharp and high hardness of the tip and strong tenecity of the matrix ;It is economical and easy to cut the hard wood and some kinds of hard material .

High hardness circular band saw blade

Made in high quality carbon tool steel,with good sharp and high hardness of the tip and strong tenecity of the matrix ;It is economical and easy to cut the hard wood and some kinds of hard material .

Good sharp band saw blade

Made in high quality carbon tool steel,with good sharp and high hardness of the tip and strong tenecity of the matrix ;It is economical and easy to cut the hard wood and some kinds of hard material .

High quality carbon band saw blade

Made in high quality carbon tool steel,with good sharp and high hardness of the tip and strong tenecity of the matrix;It is economical and easy to cut the hard wood and some kinds of hard material.

High Quality Carbide Band Saw Blade

Band saw blade is aiming at the cutting for high hardness and strong obdurabilty material,such as stainless steel,too steel ect.it is applied the special design of saw teeth and chip conveyor technique.

Carbon steel cutting band saw blade

The saw teeth aer not easy to broken,wearing and twisting even in bad condition,with high stability when cutting.And the cutting surface is more clean and smooth.

Multi-Size Caride Band saw Blades

Long cutting service life;cutting surface is clean and neat;advanced welding technique with no cracks,avoided easy to broken;we control every process in producing strictly,ensuring the high quality in products’stability.

Alloy Steel Band Saw Blade

Saw teeth adopted in the double quenching technique,its special angular design can suit for cutting various materials with more sronger chip removal ability.

Carbide Bandsaw Blade for Cutting Stainless Steel

Triple teeth set design. It is suitable for processing medium-sized and large-sized intractable materials;for Nickel-based alloy,titanium alloy,stainless steel ,tool steel,high temperature alloy,etc;the tooth hardness is 79HRC (1600HV).

41mmx1.3 Tungsten Carbide Saw Blade

The world's advanced oil quenching and continuous tempering technologies extremely improved the hardness of the tooth and the wear resistance of backing material,which made thoes two different material into perfect performance.

Hot Sale Carbon Band Saw Blades

Special heat-treatment technology solves the problems of knife bend and S bend.The straight band saw blade improves the quiet running property and the effect of saw cutting.

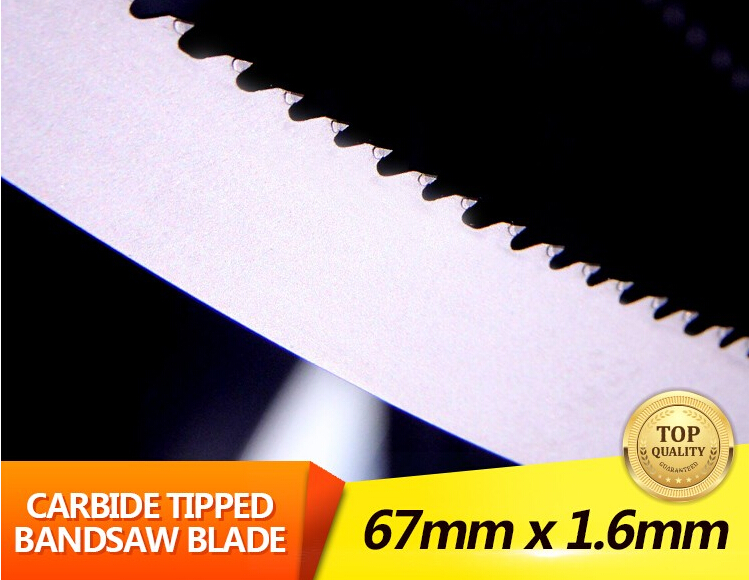

67*1.6mm carbide band saw blades

The teeth materials are made by the highest hardness Tungsten Carbide material;no matter the accuracy process and smooth surface of the products,all meet international standards.

Hard carbide tipped band saw blade wholesale

Carbide tipped band saw blade is the best grade in all series of bimetal band saw blade products;the teeth materials are made by the highest hardness Tungsten Carbide material.

Hot sell sharp carbon steel band saw blade

Direct selling factory,reasonable and competitive price;no matter the accuracy process and smooth surface of the products,all meet international standards.

Carbide tipped band saw blade

We can make the band saw blades in coil condition or in weld loop.Some length per outer wooden case or carton.The length for coil or piece is according to your requirements.

Tungsten Circular Carbide Saw Blade

Has a particularly good corrosion resistance, Excellent oxidation resistance, High abrasion resistance,superior toughness, Suitable for wood sawing / metel / alloy steel market.

- 1

- 2

- 3

- 4

- 5