Quick Details

Description

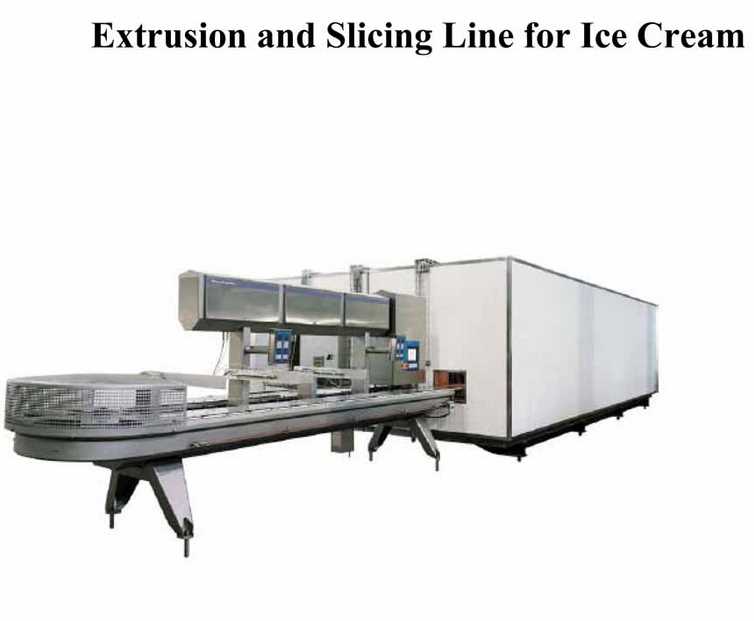

Runchen©Expro™-EX800 is used to make extrusion-type ice cream and filling-type ice cream, and it also used to decorate and harden the ice cream products. Variable types of ice cream products can be produced with auxiliary equipments.

Main power

The chain driving system and the power source of all the devices on the work platform are in the instant freezing tunnel. The driving wheels of the chain transmission system and the main driving shaft under the work platform are directly connected to the main power.

Work platform

Station frames are installed on the work platform to equip various functional parts to produce special products. These station frames are designed to be exchangeable with one other to produce extrusion-type or filling-type products. All the external surfaces and components of the platform are made of stainless steel or stainless materials.

Nominal cooling capacity 96 kw / 82,600 kcal/h

Evaporating temperature -45℃

Internal temperature of instant freezing tunnel -38℃

Distance between evaporator fins 10 mm, 12 mm, 14 mm

Quantity of fans × power consumption of each fan 6 × 1.50 kw

Total power 9 kw

Air volume 75,000 m3/h

Defrosting system water

Runchen Industry Co., Ltd. Is a professional Ice-cream solutions provider backed up by an excellent team of qualified experienced engineers with many years practical experience in the ice cream industry, either ice cream equipment manufacturers or ice cream factories.

Runchen mainly provides services for ice cream factory in below areas:

* Make and sell standard and customized ice cream manufacturing equipment

* Ice cream factory process and layout design, service facility capacity design and engineering installation

* Products innovation

* Factory management, training and consultant

* Expert and experienced in

process and reducing conversion cost