Quick Details

Description

Function Characteristics:

●Flame retardant, non-pollution, it can be installed directly in the load center.

●Maintenance-free, easy to be installed, low operating costs.

●The enclosure can be of Good moisture resistance, transformer can be put into operation without pre-drying under 100% humidity in the normal operation.

●Low loss, light weight and small volume, low noise, good dissipation of heat, it can be 150% rated load operation under forced air cooling conditions.

●Equipped with a complete temperature protection control system to provide reliable protection for the safe operation of transformers.

●High reliability. The results of checking for the products that has been put into operation show that the reliability index has reached the international advanced level.

Structural Characteristics:

Foil Coil: Adopting the entire section of copper foil, together with the F-class turn insulation, low voltage winding is wound by the special low-voltage foil winding machine. The foil coil resolves problems such as large short-circuit stress, ampere turn unbalance, poor heat dissipation, existing the winding spiral angle and unsteady manual welding quality due to low voltage and large current coil. At the same time, the end of winding is treated with cast resin, solidification to make shape, moisture-proof and anti-fouling, the lead for copper bar is welded by argon arc welding automatically.

Temperature Control Device: the transformer adopts BWDK series of signal thermometer. The temperature components are embedded in the upper half of the low-voltage coil, can detect and display the temperature of separate phase coil automatically and continuously, also have the functions of over-temperature alarm and trip.

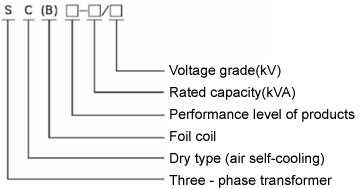

Model and Meaning

Technical Parameter for 6kV, 10kV& 30kVA-2500kVA With Off Circuit Dry Type Transformer

|

(KVA)Rated capacity

|

Voltage Combination

|

Connection Group Symbol

|

No-load Loss(W)

|

Load Loss (W)

|

No-load Current (%)

|

Short-circuit Impedance(%)

|

|

High Voltage (KV)

|

Tapping ranges of High Voltage

|

Low Voltage(KV)

|

130℃(B) (100℃)

|

155℃(F) (120℃)

|

180℃(H) (145℃)

|

|

30

|

6

6.3

6.6

10

10.5

11

|

±2.5%

±5%

|

0.4

|

Dyn11 Yyn0

|

190

|

670

|

710

|

760

|

2.0

|

4.0

|

|

50

|

270

|

940

|

1000

|

1070

|

2.0

|

|

80

|

370

|

1290

|

1380

|

1480

|

1.5

|

|

100

|

400

|

1480

|

1570

|

1690

|

1.5

|

|

125

|

470

|

1740

|

1850

|

1980

|

1.3

|

|

160

|

540

|

2000

|

2130

|

2280

|

1.3

|

|

200

|

±2X2.5%

±5%

|

620

|

2370

|

2530

|

2710

|

1.1

|

|

250

|

720

|

2590

|

2760

|

2960

|

1.1

|

|

315

|

880

|

3270

|

3470

|

3730

|

1.0

|

|

400

|

980

|

3750

|

3990

|

4280

|

1.0

|

|

500

|

1150

|

4590

|

4880

|

5230

|

1.0

|

|

630

|

1340

|

5530

|

5880

|

6290

|

0.85

|

|

630

|

1300

|

5610

|

5960

|

6400

|

0.85

|

6.0

|

|

800

|

1520

|

6550

|

6960

|

7460

|

0.85

|

|

1000

|

1770

|

7650

|

8130

|

8760

|

0.85

|

|

1250

|

2090

|

9100

|

9690

|

10300

|

0.85

|

|

1600

|

2450

|

11000

|

11700

|

12500

|

0.85

|

|

2000

|

3050

|

13600

|

14400

|

15500

|

0.70

|

|

2500

|

3600

|

16100

|

17100

|

18400

|

0.70

|

|

1600

|

2450

|

1220

|

12900

|

13900

|

0.85

|

8.0

|

|

2000

|

3050

|

15000

|

15900

|

17100

|

0.70

|

|

2500

|

3600

|

17700

|

18800

|

20200

|

0.70

|

| |

|

|

|

|

|

|

|

|

|

|

|

The load losses listed in the table are the values of the reference temperature for different insulation systems in parentheses; The load losses under other insulation system temperatures that are not included in the table should be according to their respective reference temperatures, the corresponding calculation is based on the"- 155 ℃ (F)" insulation system temperature data.

Notes: The Dimension and weight will be changed according to the requirements. These two data in the table will be subject to the factory documents.

Technical Parameter for 20kV & 50kVA-2500kVA With Off Circuit Dry Type Transformer

|

(KVA)Rated capacity

|

Voltage Combination

|

Connection Group Symbol

|

No-load Loss(W)

|

Load Loss (W)

|

No-load Current (%)

|

Short-circuit Impedance(%)

|

|

High Voltage (KV)

|

Tapping ranges of High Voltage

|

Low Voltage(KV)

|

130℃(B) (100℃)

|

155℃(F) (120℃)

|

180℃(H) (145℃)

|

|

50

|

20

22

24

|

±2.5%

±5%

|

0.4

|

Dyn11 Yyn0

|

340

|

1160

|

1230

|

1310

|

2.0

|

5.0

|

|

100

|

540

|

1870

|

1990

|

2130

|

1.8

|

|

160

|

670

|

2350

|

2470

|

3460

|

1.8

|

|

200

|

±2X2.5%

±5%

|

730

|

2770

|

2940

|

3140

|

1.8

|

|

250

|

840

|

3220

|

3420

|

3660

|

1.8

|

|

315

|

970

|

3850

|

4080

|

4360

|

1.8

|

|

400

|

1150

|

4650

|

4840

|

5180

|

1.1

|

|

500

|

1350

|

5460

|

5790

|

6190

|

1.1

|

|

630

|

1530

|

6450

|

6840

|

7320

|

1.0

|

|

800

|

1750

|

7790

|

8260

|

8840

|

1.0

|

|

1000

|

2070

|

9220

|

9780

|

10400

|

0.85

|

|

1250

|

2380

|

10800

|

11500

|

12300

|

0.85

|

|

1600

|

2790

|

13000

|

13800

|

14800

|

0.85

|

|

2000

|

3240

|

15400

|

16300

|

17500

|

0.70

|

8.0

|

|

2500

|

3870

|

18200

|

19300

|

20700

|

0.70

|

|

2000

|

3240

|

16800

|

17800

|

19100

|

0.70

|

|

2500

|

3870

|

20000

|

21200

|

22700

|

0.70

|

Technical Parameter for 35kV & 50kVA-2500kVA With Off Circuit Dry Type Transformer

|

(KVA)Rated capacity

|

Voltage Combination

|

Connection Group Symbol

|

No-load Loss(W)

|

Load Loss (W)

|

No-load Current (%)

|

Short-circuit Impedance(%)

|

|

High Voltage (KV)

|

Tapping ranges of High Voltage

|

Low Voltage(KV)

|

130℃(B) (100℃)

|

155℃(F) (120℃)

|

180℃(H) (145℃)

|

|

50

|

35

36

37

38.5

|

±2.5%

±5%

|

0.4

|

Dyn11 Yyn0

|

450

|

1340

|

1420

|

1520

|

2.3

|

6.0

|

|

100

|

630

|

1970

|

2090

|

2230

|

2.0

|

|

160

|

0.790

|

2650

|

2810

|

3000

|

1.5

|

|

200

|

±2X2.5%

±5%

|

0.880

|

3130

|

3320

|

3550

|

1.5

|

|

250

|

0.990

|

3580

|

3800

|

4060

|

1.3

|

|

315

|

1170

|

4250

|

4510

|

4820

|

1.3

|

|

400

|

1370

|

5100

|

5410

|

5790

|

1.1

|

|

500

|

1520

|

6270

|

6650

|

7110

|

1.1

|

|

630

|

1860

|

7250

|

7690

|

8230

|

1.0

|

|

800

|

2160

|

8600

|

9120

|

9760

|

1.0

|

|

1000

|

2430

|

9860

|

10400

|

11100

|

0.75

|

|

1250

|

2830

|

12000

|

12700

|

13600

|

0.75

|

|

1600

|

3240

|

14600

|

15400

|

16500

|

0.75

|

|

2000

|

3820

|

17200

|

18200

|

19500

|

0.75

|

|

2500

|

4450

|

20600

|

21800

|

23300

|

0.75

|

Baoding Zhongyi Electrical material Manufacturing Co., Ltd. is located at the beautiful Baiyangdian Science and Technology Town in Baoding City, with an advantageous geographical location and convenient transportation. Our company covers an area of 30,000 square meters, the building area of 16,000 square meters. The registered capital of the company is RMB 81,000,000.

The company mainly produces: Oil immersed power transformers, dry-type transformers, packaged substation(prefabricated substation and pad-mounted transformer), high and low voltage switchgear assembly and a variety of special transformers. There are complete necessary production and testing equipments. Our company has passed the ISO9001-2015 international standard quality management system certification. All performance indicators of the products have reached the relevant national standards and international standards.

The oil immersed power transformers and dry-type transformers have passed the Test Report of the National Supervision and Inspection Center for Energy-saving Product Quality; Complete sets of low voltage switchgear (GGD2) (GCK) has passed the test of China Compulsion Certification (CCC) from the State Bureau of Quality and Technical Supervision for Electrical Products; Indoor AC draw-out type metal clad switchgear KYN28A-12 / 1250-31.5, fixed AC metal-enclosed Ring unit XGN15-12 / 1250-31.5 and XGN15 metal-enclosed switchgears have passed the test of the National Quality Supervision and Inspection center for High-voltage Electrical Appliances Product .

Our company's products are widely used in different industries, such as power plants, chemicals, construction, mining, metallurgy, rail transportation and so on, meeting the demands of various users.

Baoding Zhongyi Electrical Material Manufacturing Co., Ltd. follows the enterprise purpose of the "details determine the success or failure, integrity casts the future", abides by the business philosophy of the "integrity based, to be innovative ambitious", we’ll always treat our customers warmly and provide qualified products and service to your satisfaction.