Quick Details

Description

1.Temperature control system and air cooling system

It applies crossflow top-blow fan which has characteristics of low noise, high wind pressure and good looking, etc., it improves the overload capability of the transformer. Adoption of intelligent temperature controller improves the safety and reliability of the operation of transformer.

2. Protective shell and outgoing bus

The shell makes further protection for the transformer. For user's option, the grade of protection has IP20,IP23,etc. Shell materials include cold-rolled steel sheets, stainless steel sheets and so on for option. The low-voltage outgoing adopts standard outgoing bus, side outgoing and top outgoing are available, or design special outgoing modes for users.

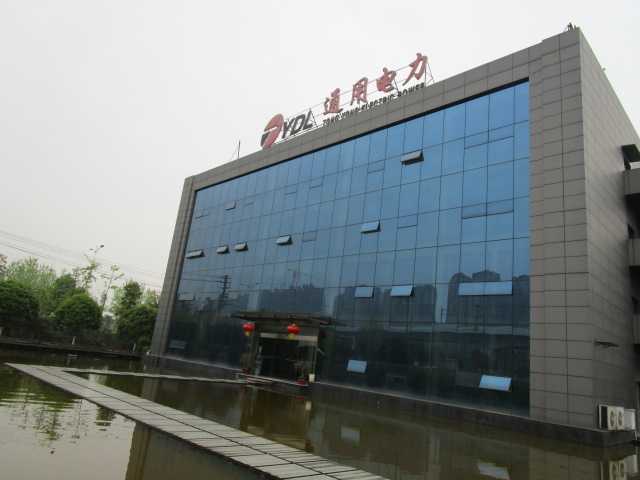

Our company possesses the advanced manufacturing equipment and process technology. Dry-type transformers production technology and techniques with the filler epoxy cast was introduced from German PC company in 2006, to complete the introduction of Germany the AsahiBES(HUBERS) , the automatic vacuum pressure epoxy cast equipment. Specializing in the production of 35KV and below the SC, the SCB series with a filler, a thin insulating epoxy resin casting dry type power transformer, dry type of special transformers, 110KV and below the oil-immersed power transformer, furnace transformer, rectifier transformer, excitation transformer, electric choke, special transformers and box-type substation. With annual production of 3million KVA output value of the production capacity of 500 million yuan.