Quick Details

Description

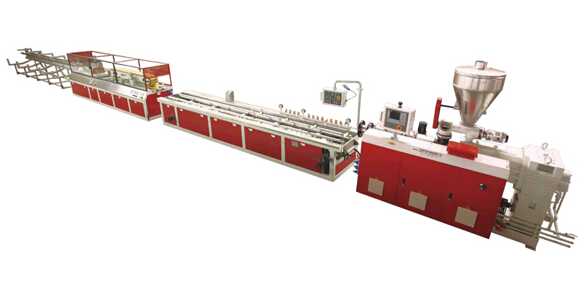

One-step way that is eliminating the middle granulation of this link. put the raw materials directly in a group of equipment, with

mixing and extruding products completed in one time. The advantage in this way is of high efficiency, mixing plastics, and

significant energy saving, lower production costs. At present, the usage in PVC class of the extrusion Plastic-wood products

gets more, but it requires more on raw materials, feeding devices, supporting the mould and extrusion equipment. And also

to the staff's overall technological level.

Suzhou Jwell Machinery Co., Ltd. Plate&Sheet Equipment Branch is the largest manufacturer of plastic extrusion machinery in China, its headoffice was located in the western district of Shanghai. There are 4 production bases, which were located in Jiading district of Shanghai, Zhoushan City of Zhejiang Province, Taicang City of Jiangsu Province and Dongguan City of Guangdong Province, totally covering areas about 700,0000 square meters. It has more than 3000 staffs, about 400 technicals and managing staffs among them. We produce more than 2000 advanced extrusion lines every year, which were exported to all country over the world.JWELL machinery has been sold across the country, and exported to all continents over the world, including the market of developed country, such as Germany,Amercia, Japan, Spain and so on.

'' Excellent Quality, Perfect All'' is Jwell' s quality policy, and all staff's working direction.

" be honest' is the core idea for us to contribute " Century JWELL"