Quick Details

Description

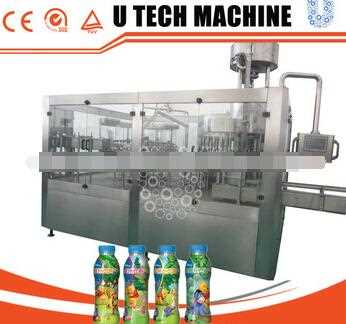

Aseptic Filling Machine Description:

1, The whole system could ensure the sterilization efficiency to 5D or 6D.

2, Wet sterilization adopts PAA which is used for sterilization of the bottle and cap after being heated.

3, The aseptic zone is realized through isolator.

4, The machine's inside classification clean room is kept through positive pressure.

5, Product capacity: 12000 BPH-42000 BPH, for tea filling, milk filling and juice filling, etc.

Technical features:

1, Multi rounds sanitizer spraying and cleaning technology to assure the safety of technics.

2, Mechanical type or electronic pulse type nozzle is of stable performance and water saving.

3, Non-contact filling head avoids cross contamination and ensures the safety of microorganism.

4, Betatron flowmeter gives the exact constant volume.

5, The capping machine is of aseptic type, self lubrication ceramics bearing, equipped with servo-motor.

6, The cap sterilizer is of soaking type or liner spraying type.

7, Automatic inspection, control and parameter record system.

8, All the key points of the production line have been taken aseptic monitoring.

Zhangjiagang U Tech Machine Co., Ltd. is a manufacturer of filling machine and packing with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beverage and other packing equipment.

Our products include: liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol, plant protein drink, etc.), barreled filling line (3-5 gallon) water treatment machines, labeling & packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC...) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

We can provide best services for customers, from plant layout, equipment manufacture and production line setup to operator training and best after-sales service. All machines are two years' service for all parts, 24 hours for engineer response (all services part 5days in customer hand by Intl' courier). Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.